3lectr1cPPC

Well-known member

Ah, missed that.

Well with tantalum caps the line indicates positive not negative, so you did that correctly, right?

68kmla.org

68kmla.org

Don't forget that negative and positive are relative. Is the negative end of those capacitors attached to a negative supply that's even further negative than ground is?

Somebody had a similar problem here:

Powerbook 540c screen problem

I got from a friend a powerbook 540c. He didn't know if it works because he hadn't power adapter and batteries. I bought a power adapter and two intelligent batteries which i connected them to the powerbook. I turned it on and it worked. It has Mac Os 8.1 installed and 36 mb ram. I left it...68kmla.org

There’s mention of a microfuse.

No, the cables are all different from what I know.

I’m 100% on the 520c/540c cables being different, not entirely sure on the grayscale ones but it’s likely there too.

@croissantking for the electrolytics you used, did you specifically pick high frequency caps for the replacements or low frequency?

Ah ok. That rules that out. Will continue pushing forward

That reminds me of a part of my PowerBook 100 repair. I was two caps short when first recapping the logic board, so I tested without them in place and the laptop worked but with no sound.

So anyway, two caps come in and I install them. Computer stops working.

I removed them, works again. Installed one of the two, works still. Installed the last, works still.

Never figured out why it did that, but it shows that weird voodoo like this can happen.

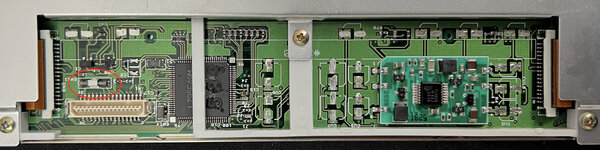

..But my question isn't about the negative marking on the electrolytics and the positive marking on tantalums. It's about the fact that on the board (as you can see from the pictures), there are clearly two caps that have the positive end connected to ground (even on the stock system). Given the stock caps were oriented this way both on my Sharp display as well as @croissantking's, I assume that's not a mistake. But I've been told that tantalums are not forgiving when they are inverted like this hence I'm asking for an expert opinion here from someone who understands more deeply the use cases where a polarized cap (stock) is inverted like this and whether it's safe to replace with a tantalum in this scenario.

I employ this method and to date have not lifted a single pad. Now that I’ve said that I’ve probably jinxed myselfI know the twist method is used but I was always paranoid that the pads might come off as you twist, so I don't do it that way.