jmacz

Well-known member

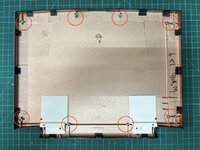

Painted Internal Chassis Frame

Used Rustoleum flat black spray paint (which has corrosion resistance). And again, will sand off the paint in any areas with metal to metal contact as I begin reassembly in the coming days.

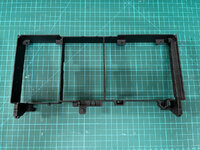

Replace Broken Screw Mounts on Lid

Modeled after @GregorHouse's design as well as YouTuber Action Retro's updates. My model is split it into two pieces because originally I was only going to do one hinge. But later discovered a crack in the other side as well so will do both. Perhaps making it one single piece (like the other two original designs) might be better but we'll see how this goes. One change is I will be using M2.5 threaded brass inserts where the screw holes are (they are in the mail). I will then use epoxy to hold the 3d printed parts to the cover.

I will probably also apply a thin coat of epoxy around each of the remaining screw mounts across the lid just to give them more strength.

Used Rustoleum flat black spray paint (which has corrosion resistance). And again, will sand off the paint in any areas with metal to metal contact as I begin reassembly in the coming days.

Replace Broken Screw Mounts on Lid

Modeled after @GregorHouse's design as well as YouTuber Action Retro's updates. My model is split it into two pieces because originally I was only going to do one hinge. But later discovered a crack in the other side as well so will do both. Perhaps making it one single piece (like the other two original designs) might be better but we'll see how this goes. One change is I will be using M2.5 threaded brass inserts where the screw holes are (they are in the mail). I will then use epoxy to hold the 3d printed parts to the cover.

I will probably also apply a thin coat of epoxy around each of the remaining screw mounts across the lid just to give them more strength.