MacOSMonkey

Well-known member

Nice - you could try just sucking out all the old solder on that device and resoldering it. Also, when the solder is out, remove the PAL/GAL and check the path from the vias to the connector / other devices.

Nice - you could try just sucking out all the old solder on that device and resoldering it. Also, when the solder is out, remove the PAL/GAL and check the path from the vias to the connector / other devices.

Don't mix them up.If you heated that area and it resolved the problem and those 2 pins were still testing as no-connects when the board was warm/working correctly, then that's probably not the issue. But, continuity might show something. Otherwise, you are down to things like: residual bad solder (previously) -- which you can infer after you re-solder the parts if the board no longer fails, or it could be a device bond wire/packaging issue or some other device issue (if not an intermittent pcb connection).

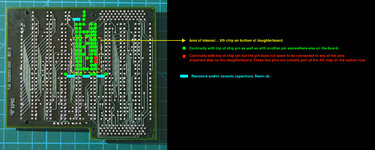

I’d say Lattice GALs from that bottom shot… have seen quite a few of them with similar markings.

If they are they can possibly be glitched to read even with the security fuse set.

Could be either 20V8 (very likely to be readable) or 22V10 (reads sometimes) in that DIP24 packaging.

So there’s hope to save the board even if they are on their way out.

Also, interestingly, the spec on Lattice GAL data retention is "in excess of 20 years." So, it's great that the accelerator still works at 34 years and fair to say that we are now in the "excess" period.

They are probably just no-connect inputs that were never tied low or high. So...what you could do is take those 2 pins and put a 10k axial pull-down on them to ground (put one end of the 10k resistor lead to nearby ground and j-bend the other end and solder it across those 2 pins). Then, if the acceleration still works when warm, they are obviously no-connects. If the problem goes away, then it is possibly because of noise injection from floating inputs plus some age-related change. If acceleration no longer works, then they are not no-connects and something else is going on. Anyway - it's an easy test that tells you everything you need to know about those 2 pins.

I'd suggest pulling them up instead.

If they're Lattice (or most other manufacturer as well) at least rev B GALs they will have internal pullups.

In case you hit a dead end with the board I'm open to examine it to figure out what type of chips they are and attempt to read/glitch them where possible.

However, for this brief test, either high or low is OK and it doesn't really matter (but not disagreeing with Bolle here ). If you're going to leave the resistor in place, then you can probably leave it high, as Bolle suggests.

If you want to narrow down the specific device, you could try making a heatshield that has an opening the size of 1 device (and downward flaps that isolate around the device and focus the heat. Then, try heating to see if you can narrow it down to a specific device.

Also, if you are sure that you don't notice any significant relative change in resistivity in the board traces when the board is cold vs. hot, then you are probably looking at a device issue. As before -- it's possibly a bond wire issue...but it could be anything. Maybe one of the cells is marginal - who knows?