I'm quite a bit older, my dad was the youngest Mechanical Engineer, right out of school on his first "real" job, when I was in first grade. So he got to "play around with" the first computer his engineering company bought, I remember the blinking lights, the punchcards and the ultra-cool block of CORE memory (I saw it as a sculpture) he had at home after IBM

recruited the crap outta' dad to be a Systems Engineer around the time Kennedy was assassinated.

We had all the Fortran, Cobol, etc. texts, THINK plaques, punch cards and all kinds of other neat stuff piled up and around the CORE memory while dad moonlighted, teaching programming at Ohio State, commuting from Springfield to IBM in Dayton in an old orange/black vinyl topped Karmann Ghia beater.

Later on, we had all the latest

Very

Large

Scale

Intgration texts laying around the house with the CORE, as the "crazy artist" firstborn, naturally I gravitated to the VERY

"art projects" of the VLSI Revolution and never got past that into programming or electronics at all. I just liked to design an "make" all kinds of crap! [

] ]'>

The Apple I came out at about the time I got out of college, where I hadn't even considered programming as I spent all my time in the printmaking shop, other fine arts classes or the darkroom.

I apprenticed at a Sign Shop while waiting for a Sales Position (adding machines!) at Burroughs where dad was at the time in Syracuse, NY after he'd done a stint at IBM's Glendale Labs in Endicott. He was on the team that developed the first 1 MegaBit Chip in the short range marketing group and my friend's dad ran IBM's "Xerox PARC" group in the same building . . .

< skips over stories about dad's leaving IBM because of political infighting and prescient observations >

. . . as I was sweeping the floor of the sign shop, bemoaning the fact that I was working for minimum wage, I realized that: They're going to automate this $^1+!

So after all that I,

finally got interested in computers and the very first production machine, the

Gerber Signmaker III hit the market after I'd moved to NYC to get married and finish my apprenticeship. After I became a partner in the business, we bought the Second Generation

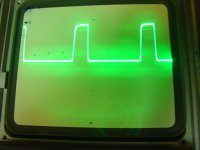

Gerber Sprint with the TTL Monitor for layout, the first Gerber had only an LED display and pen plots for design feedback. I insisted we get the "optional" 30" Plotter so that I could output entire signs or nested designs in one shot, when everyone else was outputting lines of text to "save vinyl & transfer tape" which, while expensive, cost a LOT less than the labor involved in prep & application.

Which leads to the next chapter: ( after skipping over the intervening years of my Trash-80, Commodore 64 and Tandy 1000sx intro to

realcomputing )

There I was, at the very beginnings of the automation of an industry, with a GREAT education in MicroComputing (back then you could get one just by reading a year's worth of "Computer Shopper" articles

and ads cover to cover with a few issues of BYTE, Popular Computing, Popular Science etc. thrown in for leavening!) I had Designers and Architects coming into my shop to do interactive design sessions on the screen of my Sprint! Not long thereafter, I bought a used FatMac for "home use" only because it was bundled with an ImageBanger WC, which I needed to run ThunderScan using the 15" Gerber Plotter Paper output as a carrier medium for artwork and misc. text, which was a novel "systems approach" for '87 and early '88, when Adobe Illustrator '88 was released I was all over it! I'd bought FatMac in advance of our purchase of the

MacSignMaker System, which consisted of a

Video Digitizer/B&W Security VidCam, a tripod and a just released Mac SE 1/20 with Radius16/CoPro pre-installed to drive a Plotter Interface wedged Stepper Driver Card.

To make a ludicrously looong post relatively OT and a bit abbreviated, I lived through the

TTL CookBook/Printed Circuit Engineering, Digital Typeface Design and the

PostScript (RGB?) Textbook era. While I was hooked up with a Hardware/Software Guy who did the Schematics & Code giving me the requirements upon which I designed, routed, and then plotted large scale revisions (highlighting them for clarity) on vellum for flip-charts I assembled for each incremental design revision.

I must've absorbed more from my dad's stories, his sharing his knowledge of computing and engineering with me, and "helping him with his homework" by copying the illustrations in his engineering texts from ages 3-5 as he studied on the floor of the living room of the farmhouse, than I'd ever imagined.

I wound up screenprinting the enamel resists onto CrapShack PCB Blanks, etching them, drilling them, bandsawing and filing the final shapes for my partner to solder all the TTL gate Logic, board interconnects and sockets onto the "Font Emulator" and ISA interface PCBs that I'd "made."

Now THAT was an exciting time, I was a year or more ahead of EVERYONE else in the Sign Industry, including Gerber Scientific, when I'd back-stepped into using Fontographer generated artwork and importing the PostScript Bezier Data into the MacSignMaker System as characters in a Type 3 Postscript Font, in order to get PostScript output from their Signmaker Series.

My

visual thinkers representation of very large scale plotted output, graphing each step in a letter shape, led my partner to the breakthrough realization that the "code" for Gerber's first generation Font Cartridge Format was just a series of stepped vector changes. This led to "our own" PostScript Interpreter, which translated vector art into data, filling the Gerber Font Cartridge Memory Space for "Capital A," for output on the entire SignMaker Series Font Cartridges and Translating Type 3 and later Type 1 Postscript Fonts into Gerber Format Fonts for loading into the "Font Emulator."

It seems that I'd also come up with the notion for a ROM Emulator (four Font Cartridge ROMS at a time, with the fourth ZIF socketed 32k SRAM IC being removable to act as a ROM reading station, no less) about a year or so in advance of the electronics industry.

This side business, tech company, didn't go really go anywhere for various reasons, but it kept me in cooler and cooler toys that drove a wonderfull creative frenzy/ (Hypo to full-on Psychotic) Manic Episode lasting about six months! [

] ]'> My electronics education topped out at the CMOS Cookbook and I didn't start playing around with, anything but a few custom PCBs for Plotter I/O and such, until I joined the 68kMLA.

The original mods were impressed with my knowledge of peripherals and pushing low-middle end Macs to the utmost in my business, due to financial constraints, and made me the mod of a new "Peripherals Forum."

When I started to break down mentally, it was the crazy hacking notion one-upsmanship over on 'fritter that kept me relatively functional and engaged in the virtual world as reality crumbled about me. It's been about ten years since then and I've got some of it together, after a new diagnosis, proper meds and the knowledge I need to live a

relatively sane life, enjoying this wonderful, relatively inexpensive hobby of hacking purposely lamed PaleoMacs into the machines I'd wanted them to be back when they were all I could afford.

This place keeps the Wood Geared Analog Escapement Mechanism betwixt my old ears engaged! Thanks kids! And bless the people who've

finally lubricated those Worn Wooden Wonders with the proper mixture of the right meds and saved my life!

I love this place, this hobby, and life in general, more than I ever have! :approve: