The parts came in!

They are perfect! I got a set of 5 printed gears for the Superdrive and a purple universal SCSI2SD (that's universal for v5 and v6) mount that is claimed to fit all styles of classics in the wild. Special thanks to @joethezombie for taking so much time to proof the design. He should really monetize the design, though. It's too cool to pass up.

The gears are "high detail matte", whatever that means. Doesn't seem to be polycarbonate, but it's damn dense and has a good solid feel when I scraped it with the pick. Pick up these bad boys

http://www.shapeways.com/product/M84R343FR/gears-for-macintosh-512k-vintage-floppy-drive-ejec?optionId=42282434&li=ostatus at Shapeways

You can see the teeth are very precise.

Once attached, I noticed a bit of extra noise. Maybe that's the tool marks (or dithering I guess?) making chatter while the part gets settled.

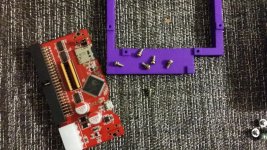

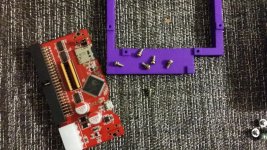

This is the mount from joethezombie.

He prints his from what I think is PLA, but I chose a material called "strong and flexible". I don't know why the company can't bother with posting up the chemical name of their plastics. I suppose it doesn't really matter since I REALLY just wanted the purple one.

Here is everything I'm fixing at the moment. Always put all the parts on the table before you get elbow deep in 2 part epoxy and bandsaws.

Assuming you have the Superdrive out of the machine already, spot the screws on the side and get them out. A torsion bar on your screwdriver will help un-seize years of neglect and abuse.

The cage slides off the main drive mechanism

Take a minute to admire the beauty of mechanical engineering that is the first generation Superdrive. It's able to read all 3.5" disks that Apple had used previous to this machine.

Now, I read somewhere that some pieces of the carriage needed to be removed. Specifically this spring.

See how it releases when the carriage is in its service position?

I don't know if that's really needed, though if you are taking time to tend to a broken cog in the works, maybe take time to put some white grease on some of the slidey bits. Remove this spring on both sides with tiny pliers or tweezers while it is in the service position.

While it's all open, take note of how the head will move. In my machine, the drive wouldn't eject so that means I need the machine to be as if it has a disk inserted so that everything will line up during reassembly. Notice how the pieces move when a disk is injected. These will need to be moved by hand to put this into the aforementioned service position.

DO NOT ALLOW THE READ/WRITE HEAD TO SCRAPE ANY TOOL, OR SLAM INTO ITS READ POSITION!!!

Violence and electronics do not make good bedfellows. Everything should be smooth, slow, and purposeful.

Undo the 2 screws holding the eject motor to the assembly.

Unplug the feed.

Remove eject motor subassembly.

Make sure the final drive gear has its (idunno...) tang in this position. 12 o'clock is where it needs to be in order to engage the carriage on reassembly. The cap there, needs to be removed with the greatest care.

The fingers holding it in place are like 300 years old and made of dead dinosaurs, so be gentle. We live in a world where the gears can be reverse engineered and printed on demand, but that took somebody nearly a century of study and almost 4 cases of really cheap beer to concoct. We don't have replacement cases yet, so be gingerly here.

I've fitted the replacement gear inside the transmission. You just have to tug at the overlapping gear in order to get at the underside. Its got a bit of greasy jelly in there, so don't worry none. Don't lick your fingers either.

Toss back the overlapping gear.

That's that!!! Reinstall the parts in the reverse order that you took them out of the case and accidentally dropped on the floor trying to get the lights just right. When I was fitting the carriage springs back into place, I just kind of shoved the disk in the hole while lifting (ever so gently as to not strain the thin bits) the read/write head. It chunked into place and the manual eject got everything lined up again. TEST before you reinstall the bucket.

As for the SCSI2SD...

Pull the hard disk from the machine and pull the 4 screws that keep the drive inside it's bracket. Throw away the screws (er, put them into your screw sorting bin over on the workbench).

Take a look at the underside of the 40MB Quanta drive (or whatever you have. I'm not psychic.) and find the 6 smallish dark screws holding the logic to the drive. We want them to live on!

Layout the parts and inspect everything for burrs or artifacts or liens or unpaid library fines...

See where your mount will line up with the bracket (if you have one) and use 4 of those screws we just liberated from the old drive to secure it in place. DO NOT OVER TORQUE! There's no need to tap, since the plastic is pretty fine. But I can tell you that it sure felt like one of those is just a bit too small and about to slip in its threads.

You see that joethezombie made sure there is a bit of relief for the molex plug on one side? This is the only way the SCSI2SD will fit on the mount.

And if you're pretty savvy (unlike green ol' me) you'll see right here where my interest in aesthetics monkeyed up my installation.

Don't forget to attach the activity LED. It works just fine!

Then if you get fed up with twisting and fighting your SCSI cable, you can flip over the assembly, mount the thing properly in the bracket, and everything BUT the LED leads will fit just right. I made a choice.

Again, TEST TEST TEST!!! And do it before completely closing up the case. It's always easier to bench test a component when you don't have the daunting task of yet another teardown between you and a properly working kit.