Westinghouse

Well-known member

It is. My intent was to use off-the-shelf 1.2v NiMH rechargeables - I thought I could use 6 cells, but in actual practice 6 cells gave over 8v, and I decided to play it safe with just 5, which yeild about 6.6v.

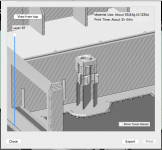

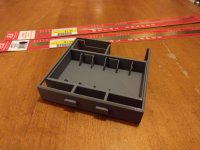

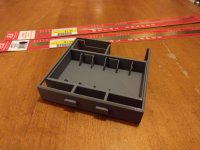

Here are some pics of how it turned out. This works, but as it's a prototype I'd like to make a few tweaks before I post up the .stl - some improvements.

BTW constructive criticism and questions are welcome.

Here are some pics of how it turned out. This works, but as it's a prototype I'd like to make a few tweaks before I post up the .stl - some improvements.

BTW constructive criticism and questions are welcome.

Last edited by a moderator: