You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

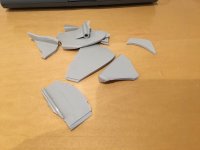

Brittle plastic OMG!

- Thread starter pcamen

- Start date

EvilCapitalist

Well-known member

Ouch, that's too bad. Spindler plastic strikes again :sadmac:

I've gotten to the point that I try and handle just about anything Apple from the mid-late 90s (5xxx, anything Outrigger (72/73/75/76xx, Beige G3 DT), and 85/95xx) as little as possible. Back when I had a Performa 5200 it made some very worrying creaks just adjusting the tilt, to say nothing of picking it up where it felt like the case was flexing.

Given that the cracks and missing plastic appear to be at or very near the CRT's mounting points I wonder if it would make any difference to handle them with the glass facing down. Meaning instead of carrying it like a normal monitor by holding on to the sides with the glass facing back towards you, carrying it by holding the sides of the front bezel with the glass facing down.

I've gotten to the point that I try and handle just about anything Apple from the mid-late 90s (5xxx, anything Outrigger (72/73/75/76xx, Beige G3 DT), and 85/95xx) as little as possible. Back when I had a Performa 5200 it made some very worrying creaks just adjusting the tilt, to say nothing of picking it up where it felt like the case was flexing.

Given that the cracks and missing plastic appear to be at or very near the CRT's mounting points I wonder if it would make any difference to handle them with the glass facing down. Meaning instead of carrying it like a normal monitor by holding on to the sides with the glass facing back towards you, carrying it by holding the sides of the front bezel with the glass facing down.

Byrd

Well-known member

I feel your pain , and frustration - sometimes it's an annoying hobby

Of similar era, I pulled apart a black teardrop ADB mouse recently for cleaning. About ten chunks came off it from hardly any force. It continued to fleck chunks off while I cleaned it. Definitely not rough play, just cheap shitty plastic from the time. It's all repaired and back together now, but I'm wary of doing this again ...

Of similar era, I pulled apart a black teardrop ADB mouse recently for cleaning. About ten chunks came off it from hardly any force. It continued to fleck chunks off while I cleaned it. Definitely not rough play, just cheap shitty plastic from the time. It's all repaired and back together now, but I'm wary of doing this again ...

pcamen

Well-known member

So, has anyone ever tried to make brittle plastic less brittle? Out our curiosity, I googled that idea and came up with this page:

https://goldwingdocs.com/forum/viewtopic.php?t=12060

https://goldwingdocs.com/forum/viewtopic.php?t=12060

My dad was a plastics engineer for 30+ years. One of the best tips he has given me thus far is to rejuvenate and limber up old and new thermoplastic polymers by soaking them for a minute or so in boiling water. The results with nylon can be especially dramatic. Yellowish nylon goes into the water brittle and comes out supple and milky white. New composite thermostat housings, foosball table handles, and other plastic pieces that must be mounted to metal become slightly more flexible and are an easier and better fit.

The boiling water does not melt the plastic. Soaking nylon in room temperature water for a long time has the same impact as a short bath in boiling water. The chemistry is too complex for just the son of a plastics engineer to explain. Basically the moisture releases tension between polymer molecules that was created when the plastic was first made (molded, extruded, etc.) or that built up over time as the plastic was exposed to sunlight, heat, chemicals or otherwise aged.

dcr

Well-known member

I did. I think I had a thread on it here or posted in a thread, but that was a couple years ago when I first joined the forum.So, has anyone ever tried to make brittle plastic less brittle?

I had some broken pieces and was willing to use them to experiment. I *think* I tried the boiling water method and it didn't make the plastic any less brittle. I think I tried a second method too and that also didn't work. All I remember for certain is that nothing I tried worked.

I still have plastic pieces here I can try stuff out on so if anyone has any other ideas to try, I'll give it a go, within reason.

Trash80toHP_Mini

NIGHT STALKER

I've read that the plasticisers leach out as well, causing brittleness, everything-you-need-to-know-about-abs-plastic has some interesting info, especially the glass transition/melting point of ABS. Adding-salt-increases-water-boiling-point so adding a lot of it might work better by reaching a bit closer to the melting point ABS. Using a boiler to raise the temperature of superheated steam for the task might work a lot better, that or putting the plastics inside the boiler? Dunno, but if it works, jury rigging a redneck boiler contraption to do the deed would make one hella YouBoobTube video. :lol:

Unknown_K

Well-known member

What are you trying to do warp the hell out of the plastic?I've read that the plasticisers leach out as well, causing brittleness, everything-you-need-to-know-about-abs-plastic has some interesting info, especially the glass transition/melting point of ABS. Adding-salt-increases-water-boiling-point so adding a lot of it might work better by reaching a bit closer to the melting point ABS. Using a boiler to raise the temperature of superheated steam for the task might work a lot better, that or putting the plastics inside the boiler? Dunno, but if it works, jury rigging a redneck boiler contraption to do the deed would make one hella YouBoobTube video. :lol:

Trash80toHP_Mini

NIGHT STALKER

I doubt it would warp if you got only half of the way to the melting point? Dunno, testing at different temps would be done first, obviously. Come to think of it, testing in an oven at different temps would be an interesting exercise. [ ]

]

Similar threads

- Replies

- 32

- Views

- 3K

- Replies

- 4

- Views

- 2K