@Swolfington Quite an old request but just in case: the drawings for this part (Q800 CD bezel) are in the Developer Note for the Q800, as one of the foldout.The only part I am not really sure about are the two flang/clip things on the rear right side. I have like 3 different bezels in front of me, and none of them have any of those left, attached or otherwise. If anyone out there can take a picture and/or measure of a non broken one

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D-Printed Objects

- Thread starter 360alaska

- Start date

Did anyone have a go at making a model of these yet? I would *love* a set for my IIfx. Surely someone on the forum has these Kensington stands and could make measurements even if they don't want to make a model?

Well... literally after posting this I noticed that someone did do it:

3D-Printed Objects

Has anyone ever found or made a model of the hard drive sled for the Performa 6200 line (and maybe others?). Mine was very brittle plastic and kinda crumbled as I took it out, but it doesn't seem like it would be overly difficult to model. I'd take a crack at it myself, but I don't have any idea...

68kmla.org

68kmla.org

But the originals were metal, so not sure if they are suitable for plastic - has anyone tried them?

Thanks to @jessenator there is now a modified 3D model of the Mac II stands which I have ordered a set of to test. Printing larger models starts to get expensive so hopefully they work OK.

Trash80toHP_Mini

NIGHT STALKER

Sweet, can't wait to hear about your results. Printed ABS version may need more thickness? Are SLA printed parts inherently stronger than ABS, I'd think so?

jessenator

Well-known member

After a night's sleep, I think something like nylon would be more hard-wearing.Thanks to @jessenator there is now a modified 3D model of the Mac II stands which I have ordered a set of to test. Printing larger models starts to get expensive so hopefully they work OK.

PLA is not very stiff, and doesn't deal well with heat. I would think ABS is better in most ways (Lego bricks seem indestructible!), but I haven't tried it myself - as I read somewhere it emits not-so-good-for-you stuff when heated to printing temperature, and my printer is in my home office.

I had to make PCIe brackets for some InfiniBand adapters (replacing low-profile with high-profile), and PLA just couldn't cut it; I had to witch to some nylon-based filament to get enough stiffness - though the material is quite brittle, the thin part will break from torque a lot sooner than PLA which just bends. But for my use case it's fine, it keeps the PCIe board in place despite the heavy IB cable.

And for 'internal' structures inside a computer, beware the heat; the 'expansion/backplate' part of the SBusFPGA (pictures here, the blue stuff) will weaken and after a while visibly deform from the weight of the PCBs simply from being heated by the neighboring MBus CPU modules in the machine. And that's with modules that aren't particularly hot.

I had to make PCIe brackets for some InfiniBand adapters (replacing low-profile with high-profile), and PLA just couldn't cut it; I had to witch to some nylon-based filament to get enough stiffness - though the material is quite brittle, the thin part will break from torque a lot sooner than PLA which just bends. But for my use case it's fine, it keeps the PCIe board in place despite the heavy IB cable.

And for 'internal' structures inside a computer, beware the heat; the 'expansion/backplate' part of the SBusFPGA (pictures here, the blue stuff) will weaken and after a while visibly deform from the weight of the PCBs simply from being heated by the neighboring MBus CPU modules in the machine. And that's with modules that aren't particularly hot.

Trash80toHP_Mini

NIGHT STALKER

Interesting about heat deformation and brittleness.

I've been toying with the notion of complex metal part fabrication using laser or water jet cut blanks for quite some time now. I did a lot of sheet metal and iron work fabrication in my business and for fun in the day.

Having lost my big box and pan brake down the storage room whirlpool, I've been making due with hand tools on a much smaller scale. Also, even with brake at hand, complex forms done in punching and stamping processes used for computer parts were always off limits, so I've been wondering about alternate methods.

Lay out a complex bend component for computer chassis/support purposes with a series of holes along the bend lines and suddenly available hand tools become adequate for the task.

I've been toying with the notion of complex metal part fabrication using laser or water jet cut blanks for quite some time now. I did a lot of sheet metal and iron work fabrication in my business and for fun in the day.

Having lost my big box and pan brake down the storage room whirlpool, I've been making due with hand tools on a much smaller scale. Also, even with brake at hand, complex forms done in punching and stamping processes used for computer parts were always off limits, so I've been wondering about alternate methods.

Lay out a complex bend component for computer chassis/support purposes with a series of holes along the bend lines and suddenly available hand tools become adequate for the task.

jessenator

Well-known member

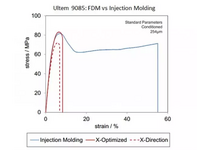

I'm curious to know more here. Sure, it doesn't flex like PETG, or even what little flex there is in PLA, but for things like clamps and static objects holding a load, I've seen good results. Nylon tools I've used—made by the guy who got me into printing—last FAR and AWAY longer than PLA tools I've printed and far less brittle. The stank and general PitA nature of ABS setup wasn't worth it to us. Getting it done by someone else? another story, perhaps. Also, FWIW, injection mold ABS is much stronger than FDM:nylon-based filament to get enough stiffness - though the material is quite brittle

The redesign is, as was stated, a test, and joshc knows that. I'm not an engineer, I just like to make things

Also, I'm curious how much heat a IIfx actually radiates through the case. Anecdote: I printed a (PLA) shower head bracket replacement and it's been installed for over 3 years now with only a small chip on the corner falling off (an exposed impact point for the head) after daily use in a hot and humid environment.

Yes, I know PLA will DEFINITELY deform. I printed some columns in black PLA and left them in the sun for all of 10 minutes in summer while I went to fetch something and they were already drooping...

Trash80toHP_Mini

NIGHT STALKER

Almost certainly not enough to consider. The RFI shielding also acts as a heat shield/spreader protecting case plastics all around. In the IIfx and its ancestors, there is an air gap between PSU case and the RFI shielding. From the looks of the auction pics, there's a gap between top and bottom surfaces of case and sides of the stand. That likely makes room for rubber or maybe felt bumpers that prevent scratches and therefore insulation for plastic replica feets.Also, I'm curious how much heat a IIfx actually radiates through the case.

I don't have much data to supply; I'm not even sure what the filament was made off - it's Colorfabb XT, but the current description of that product doesn't match my recollection of what I bought (probably around 7-8 years ago...), they could have changed it? But my memory could be faulty and it might not be Nylon at all, after all.I'm curious to know more here.

Anyway, it's a PCIe bracket of regular width with just as small extra vertical 'bar' to help with stiffness. It's stiff enough to hold an heavy IB cable in place (same as a 4x SAS copper cable), but if you try to 'roll'/'bend' it, it tends to break fairly soon rather than deform. PLA of similar thickness tends to bend a bit more and come back to true, and if you force it will permanently deform rather than cleanly break, unless you really pinch it. I'm even less a mechanical engineer than an EE, so that's the best I can offer.

Yes, FDM is clearly less than ideal for good structural integrity. But it's a lot easier to do at home

Hot showers are hot, but presumably less so than a pair of passively cooled BiCMOS CPU with external cacheAnecdote: I printed a (PLA) shower head bracket replacement and it's been installed for over 3 years now with only a small chip on the corner falling off (an exposed impact point for the head) after daily use in a hot and humid environment.

Is the new model available somewhere, and is it any smaller than the version posted by @joethezombie you linked to earlier? This thing is too large for my printer (I figure if they work for a II they should work for a IIci as well?).Thanks to @jessenator there is now a modified 3D model of the Mac II stands which I have ordered a set of to test. Printing larger models starts to get expensive so hopefully they work OK.

Trash80toHP_Mini

NIGHT STALKER

IIci is low enough that it doesn't need the full tower config's outrigger feets. You had me thinking about trying my MDF fabbed Q700 high heels made for using on carpet, but stability would be the issue there.

Now you have me thinking of coming up with a hardwood version inspired by the front leg of one of the Lisa prototypes that happens to be in the DigiBarn collection. Couldn't find the good pic of the leg in my collection, but you can catch glimpses of it here: https://www.digibarn.com/collections/systems/apple-lisa1/lisa1-prototype/index.html

Now you have me thinking of coming up with a hardwood version inspired by the front leg of one of the Lisa prototypes that happens to be in the DigiBarn collection. Couldn't find the good pic of the leg in my collection, but you can catch glimpses of it here: https://www.digibarn.com/collections/systems/apple-lisa1/lisa1-prototype/index.html

OK thanks. Don't think I've ever seen a IIci and a II/IIx/IIfx side-by-side, didn't realize they were very different.The model hasn't changed in size, it's for the II, IIx and IIfx. The IIci is entirely different dimensions to the earlier II series. These stands were never made for the IIci.

jessenator

Well-known member

Since the modified design was essentially built as a half (to be mirrored), it could be resized for a compact II/Q700. The height might be a bit of overkill

(The width for the one on the right was an aborted test for a bernoulli box portable)

Thanks! Clearly quite different in look with the recess on the IIfx... Thinking about it, I might not have actually seen a II{,x,fx} in the flesh; only compacts, shortened II (IIcx, IIci) and various Quadras in the 68k days. I've always thought of the IIcx as a 'cut down IIx', but while that may be true architecture-wise, it's clearly not true for the casing.This should give you an idea, a Quadra 700 and IIci next to a IIfx.

I've learned something new today, thanks for the picture.

... and now I want a II or IIx (IIfx are too expensive and sought-after), but that well seems dry in France.

Swolfington

Well-known member

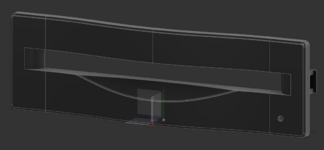

Thanks for the link! I came across that as well way back when and it was a tremendous help nailing down some of the smaller details. Incidentally, I actually made the caddy loading drive version of that bezel not too long ago as well. I haven't tried printing it out and I don't have a functional caddy loading drive to test it on, but assuming those technical drawings are accurate, it should work.@Swolfington Quite an old request but just in case: the drawings for this part (Q800 CD bezel) are in the Developer Note for the Q800, as one of the foldout.

Attachments

Similar threads

- Replies

- 11

- Views

- 1K