You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

I was poking at 7.1.1 Pro out of curiosity, since one of my disk images had it for some reason. (I'm already sold on 7.1 with the System Update and everything, very aware of Pro's reputation and status.) However, I noticed that the startup time is abysmal, even on zero-wait Mac II-family emulators. Even After Dark screensavers seem to hitch a bit, indicating context switches to some kind of background process. What did they stuff the System File with? Is this the true power of PowerTalk?CChuckdubuqueQT, PC Exchange, AppleScript add some overhead, but it's mostly PowerTalk. Almost nothing new in the system files.

BoctorThat's what I figured from looking more closely at the resources. I think TokenTalk is even included by default.My SE/30 logic board (my only LB not washed/recapped solely by me) is riddled with residual corrosion. I can smell it when reflowing. It's my fault for believing the person who sold it was a professional in the first place, but this was ~10 years ago, when I would've made all these same errors. Should I dare trying to lift every single SMT component with hot air? Go for a Reloaded PCB?

BoctorThat's what I figured from looking more closely at the resources. I think TokenTalk is even included by default.My SE/30 logic board (my only LB not washed/recapped solely by me) is riddled with residual corrosion. I can smell it when reflowing. It's my fault for believing the person who sold it was a professional in the first place, but this was ~10 years ago, when I would've made all these same errors. Should I dare trying to lift every single SMT component with hot air? Go for a Reloaded PCB? PhipliIf that doesn't fix the voltage sag, it might need the PSU recapping if it hasn't been already.

PhipliIf that doesn't fix the voltage sag, it might need the PSU recapping if it hasn't been already. BoctorI have the fancy aftermarket Meanwell PSU, I had no idea about the trimpots in the stock ones. This is for sure a LB issue, I found smelly gunk under multiple ICs. The last person likely didn't clean at all before recap. Since I can't guarantee the integrity of the inner layers or vias, I'm strongly leaning towards attempting a Reloaded PCB. I know it's normally uncalled for at this point, but I have the itch.

BoctorI have the fancy aftermarket Meanwell PSU, I had no idea about the trimpots in the stock ones. This is for sure a LB issue, I found smelly gunk under multiple ICs. The last person likely didn't clean at all before recap. Since I can't guarantee the integrity of the inner layers or vias, I'm strongly leaning towards attempting a Reloaded PCB. I know it's normally uncalled for at this point, but I have the itch. PhipliOK, but as long as the loaded voltage on the new PSU is above 4.95V on the 5v Rail, higher if possible.Disappointingly, it seems like flashing a Dell-branded OEM Rage 128 Ultra with the PowerMac Rage 128 Pro VBIOS does not automagically work. I didn't expect it to, but it was at least worth finding out.

PhipliOK, but as long as the loaded voltage on the new PSU is above 4.95V on the 5v Rail, higher if possible.Disappointingly, it seems like flashing a Dell-branded OEM Rage 128 Ultra with the PowerMac Rage 128 Pro VBIOS does not automagically work. I didn't expect it to, but it was at least worth finding out. obsoleteOh my, this is an AGP card? Are you doing it just for the challenge? Otherwise, I would send you a Radeon 7000 for free. I have extras.

obsoleteOh my, this is an AGP card? Are you doing it just for the challenge? Otherwise, I would send you a Radeon 7000 for free. I have extras. obsoleteThe first issue I see is that this PC card has two 32-bit SDRAM chips (64-bit bus) for 16MB, and the Mac cards have eight 16-bit SDRAM chips (128-bit bus) for 32MB. Some later ATI cards still work despite this (and just report the wrong memory size), but maybe this is a showstopping problem for the Rage 128. Not many people have experience flashing them because they're the lowest-end AGP Mac video card.

obsoleteThe first issue I see is that this PC card has two 32-bit SDRAM chips (64-bit bus) for 16MB, and the Mac cards have eight 16-bit SDRAM chips (128-bit bus) for 32MB. Some later ATI cards still work despite this (and just report the wrong memory size), but maybe this is a showstopping problem for the Rage 128. Not many people have experience flashing them because they're the lowest-end AGP Mac video card. BoctorI was doing it purely for challenge, yeah. I could have sworn some of the Mac R128 cards had 16M and the same "R128P" GPU, but the bus would probably be a showstopper. I ended up putting back the stock GeForce2 MX and fixing my cheap SiL3112 card instead, which turned out better. (It was the typical out-of-spec 3.3V VRM issue. If I recall, you had also posted the name of the replacement part, so thanks!)Would it be wise to preemptively recap a PM7200 logic board ASAP? Nothing's gone bad yet. I'm unsure if this is as urgent as with the woefully leaky, late-80's SMT electrolytics, which seemed to go bad much sooner (and with more of a mess) than later-generation ones. I know the need for new caps is an eventuality, but it may be a while before I can break out the soldering tools again.

BoctorI was doing it purely for challenge, yeah. I could have sworn some of the Mac R128 cards had 16M and the same "R128P" GPU, but the bus would probably be a showstopper. I ended up putting back the stock GeForce2 MX and fixing my cheap SiL3112 card instead, which turned out better. (It was the typical out-of-spec 3.3V VRM issue. If I recall, you had also posted the name of the replacement part, so thanks!)Would it be wise to preemptively recap a PM7200 logic board ASAP? Nothing's gone bad yet. I'm unsure if this is as urgent as with the woefully leaky, late-80's SMT electrolytics, which seemed to go bad much sooner (and with more of a mess) than later-generation ones. I know the need for new caps is an eventuality, but it may be a while before I can break out the soldering tools again. BoctorStill works, thankfully. I was afraid I'd crush the poor PPC601 while working! The HS doesn't even get warm before than the fan can pull air away from it, and the CPU lacks the discoloration/delamination you sometimes see in 6100/7100 boards. Seems like that rotated cooler design was a big improvement. I snuck in a surprise, too: A reflashed/resoldered SIL3112 SATA card, which it happily boots from.

BoctorStill works, thankfully. I was afraid I'd crush the poor PPC601 while working! The HS doesn't even get warm before than the fan can pull air away from it, and the CPU lacks the discoloration/delamination you sometimes see in 6100/7100 boards. Seems like that rotated cooler design was a big improvement. I snuck in a surprise, too: A reflashed/resoldered SIL3112 SATA card, which it happily boots from.Attachments

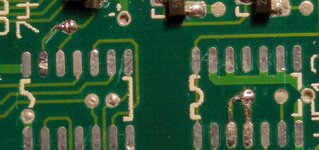

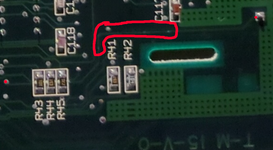

Managed to ruin the ends of three traces while removing dead mask ROMs, only on the final chip. Everything was going smoothly until the last possible moment. At least the bodge wires will end up snugly pinned beneath the DIP socket, but it'll be weeks before I forgive myself for blemishing such a pretty logic board...My "new" IIci's soft power was stuck always signaling on, but I found the three micro-breaks in the relevant traces. Wish I'd spotted them during the board washing, but oh well. Humorously, both could've been fixed by simply bridging pins, but I wanted to make this look as elegant as I could, so as not to confuse any future owners.Attachments

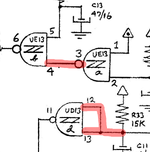

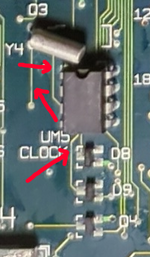

Got a hold of a cheap IIci and made the logic board sparkle again. Lifted dull-looking chips, cleaned the legs and pads, drag-soldered back fresh. Nice new caps, no broken traces in the acid zones, power circuit works. However, either the ROMSEL circuit or the ROM chips themselves are again bad, like in my IIcx, though the machine works great with a slot ROM. Am I cursed to irradiate every mask ROM I touch?! BoctorI never thought I'd see the day, although I read somewhere that latent manufacturing problems in these can crop up after a couple decades. Unsure how true this is. I'll have to learn new desoldering techniques, or see if I can get to VCF some day and consult an expert, as it's hard to get some of those DIPs out and I don't want to ruin my boards. Good thing there's always the SIMM slot!I'd seen mentions of cursors flickering on some Macs because of time/RTC related problems. After taking a closer look at the RTC circuitry in my cheap Mac IIcx, sure enough, it's not the video card! After scraping, tinning, and meticulous bodging, it's all right.

BoctorI never thought I'd see the day, although I read somewhere that latent manufacturing problems in these can crop up after a couple decades. Unsure how true this is. I'll have to learn new desoldering techniques, or see if I can get to VCF some day and consult an expert, as it's hard to get some of those DIPs out and I don't want to ruin my boards. Good thing there's always the SIMM slot!I'd seen mentions of cursors flickering on some Macs because of time/RTC related problems. After taking a closer look at the RTC circuitry in my cheap Mac IIcx, sure enough, it's not the video card! After scraping, tinning, and meticulous bodging, it's all right.Attachments

BoctorThanks! The Xenforo search and the high-quality threads on this site are an amazing combo. Learning about the clock/PRAM circuit from the forums also alerted me to a broken trace and possible hidden corrosion on my IIsi, which I never would've otherwise caught.

BoctorThanks! The Xenforo search and the high-quality threads on this site are an amazing combo. Learning about the clock/PRAM circuit from the forums also alerted me to a broken trace and possible hidden corrosion on my IIsi, which I never would've otherwise caught. IescaWere you also experiencing issues with clock drift, in addition to the cursor symptoms?

IescaWere you also experiencing issues with clock drift, in addition to the cursor symptoms? BoctorNot sure if I'd call it drift, but on the IIcx, a second took a very long time to elapse. Apple Personal Diagnostics won't specify why the Logic Board Components test fails, but it'll actually fail when the 1hz on the clock doesn't tick as expected, whereas Snooper and MacTest Pro don't even test it.

BoctorNot sure if I'd call it drift, but on the IIcx, a second took a very long time to elapse. Apple Personal Diagnostics won't specify why the Logic Board Components test fails, but it'll actually fail when the 1hz on the clock doesn't tick as expected, whereas Snooper and MacTest Pro don't even test it. -

Loading…

-

Loading…

-

Loading…