Tashtari

PIC Whisperer

Just a little Saturday project. Introducing: TashIO!

github.com

github.com

Elevator Pitch

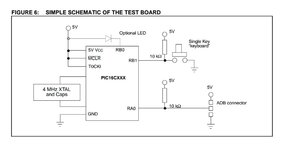

It's a clone of BeeHive Technologies's ADB I/O, a device with analog and digital I/Os for automation, control, and interfacing to sensors and other devices. It has existing software support in C, RealBASIC, Fourth Dimension, and HyperCard, to name just a few.Project Status

Firmware is nascent but feature-complete and passing tests.Caveats

Somewhat more than my other projects, this really wants a full-blown PCB with relays, protection circuitry, &c., and this goes a bit beyond my skill set. Any volunteers?Code

GitHub - lampmerchant/tashio: Clone of BeeHive Technologies's ADB I/O.

Clone of BeeHive Technologies's ADB I/O. Contribute to lampmerchant/tashio development by creating an account on GitHub.