mactjaap

Well-known member

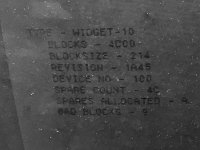

I restored a widget drive to a certain point. See my old posting:

it it works on a “donor” external PSU. The problem is that it is very hard to start. To get it on I have to fiddle with the power on/off switch on the PSU. It helps if you spin the disk counter clockwise and then do the power trick.

Some questions:

- What can I do to let it start more easy? Can I lubricate it? Or can I adjust the motor?

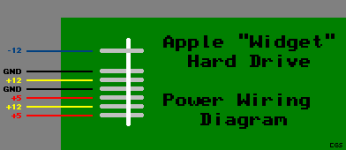

- I don’t have a power harness. Can I use some connections on the power supply or board?

- is there a better way to power switch the disk on with its external power unit? Should I use a kind of special switch?

- how to get the special power connector for the drive. Is it only for a widget or is it some kind of standard?

it it works on a “donor” external PSU. The problem is that it is very hard to start. To get it on I have to fiddle with the power on/off switch on the PSU. It helps if you spin the disk counter clockwise and then do the power trick.

Some questions:

- What can I do to let it start more easy? Can I lubricate it? Or can I adjust the motor?

- I don’t have a power harness. Can I use some connections on the power supply or board?

- is there a better way to power switch the disk on with its external power unit? Should I use a kind of special switch?

- how to get the special power connector for the drive. Is it only for a widget or is it some kind of standard?

Last edited by a moderator: