I have a Lisa 2/10 H/88 that was defect when I bought it 10 years ago. There was a problem with the static RAM but with excellent help from this forum ( stepleton and mactjaap) its now working, except for the widget harddrive. Now its time to try to repaire the harddrive. When starting I get the error code 82 from the harddrive. The harddrive has never started to rotate before as long as I have own it.

I adjusted the solenoid as described in Larry Pinas Macintosh Repaire and upgrade secrets p 264. The actual clearance was 0.050 and was adjusted to 0.012.

I opened the harddrive and pictures as shown.

After starting the Lisa I rotated the harddrive and for the first time it started to spin. First slowly but increased in speed. The sound was similair to the old harddrive in Macintosh II. After 15-20 sec it stopped. Some popping from the widget and smell of smoke. I turned it of. Not good.

The front of the widget was warm and the Q3 on the motor board was hot. I started it again but no action in the drive.

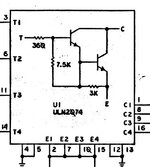

The Q3 is not working when tested, see pictures

Probably Q3 was burned and the motor stopped. Its easy to replace Q3 but should I also replace U1 , ULN2074, the quad Darlington chip?

https://www.applefritter.com/content/schematic-motor-control-widget-050-5023-b

When I look at the pictures of the hardrive now I noticed that the glass platter is probably displaced, no screw as the pictures in https://68kmla.org/bb/index.php?threads/apple-lisa-widget-drive-repair-need-some-advise.35420/

Should it be screwed or glued?

Thankful if anybody has any suggestions what to do.

I adjusted the solenoid as described in Larry Pinas Macintosh Repaire and upgrade secrets p 264. The actual clearance was 0.050 and was adjusted to 0.012.

I opened the harddrive and pictures as shown.

After starting the Lisa I rotated the harddrive and for the first time it started to spin. First slowly but increased in speed. The sound was similair to the old harddrive in Macintosh II. After 15-20 sec it stopped. Some popping from the widget and smell of smoke. I turned it of. Not good.

The front of the widget was warm and the Q3 on the motor board was hot. I started it again but no action in the drive.

The Q3 is not working when tested, see pictures

Probably Q3 was burned and the motor stopped. Its easy to replace Q3 but should I also replace U1 , ULN2074, the quad Darlington chip?

https://www.applefritter.com/content/schematic-motor-control-widget-050-5023-b

When I look at the pictures of the hardrive now I noticed that the glass platter is probably displaced, no screw as the pictures in https://68kmla.org/bb/index.php?threads/apple-lisa-widget-drive-repair-need-some-advise.35420/

Should it be screwed or glued?

Thankful if anybody has any suggestions what to do.