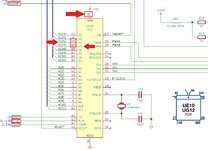

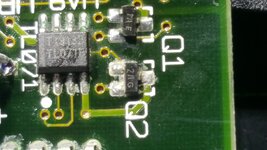

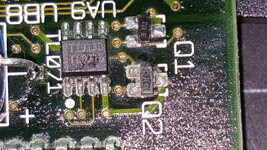

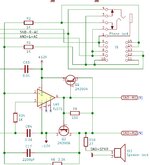

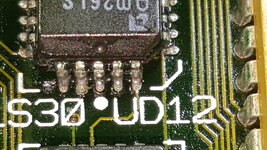

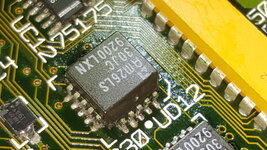

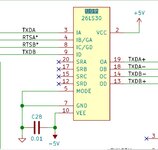

TL071 is an audio amplifier and 26LS30 is a serial port line driver (an electronic circuit that amplifies a signal and drives it along a transmission line or cable)

Thanks for the info, I really appreciate it! So many sound chip problems on this board.

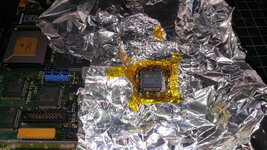

SE/30 will not boot without ASC. I tried it on multiple boards. (simasimac)

26LS30 will not prevent a boot

TL071/Q1/Q2 issue will make you unable to hear the death chime if there's one from the speaker, they are audio amplifier/driver to drive internal speaker. Line-out jack should work fine without those.

This is giving me hope, thank you!

I've looked this board all over, and there is no other corrosion near the CPU, RAM, ROM, or muxes. It was starting to worry me that fixing the ASC wouldn't cure the simasimac, or even have a chance of doing so; really glad to hear a missing/broken ASC can and will halt a boot.

I'm certain that these logic board problems were caused by the cap corrosion, the broken traces/areas of the board must be in those limited locations where the leaks occurred, which makes it easier to find the problem, visually. Having to find the problem with just a scope and meter alone, would probably not work out well for me even though I do have both, and an ancient lightweight electronics degree.

Will give it another go tomorrow night.

Thanks again for the info and reply guys!