The best advice I can give is, get something else that's easier to work on, after you've practiced your soldering skills and got the necessary equipment. You can't repair a board like this with just a soldering iron. You will likely need a hot air station and a desoldering gun (a proper one).

The board isn't clean enough for this yet, I can see lots of residue...something, around all the pins.

View attachment 65164

How has this been cleaned? Vinegar, a soap scrub, IPA is probably the minimum I would do.

The ROM SIMM

socket will likely need replacing - look at the pins, they are corroded. It's not easy to replace the socket without a vacuum pump desoldering gun - and cheap ones tend to be not very good.

View attachment 65165

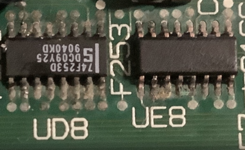

Look at how crusty, corroded and damaged the pins on these chips are:

View attachment 65166

You need a hot air station and you would need to learn how to use it, in order to pull these chips off and replace them.

The other obvious thing that needs doing is all the capacitors need replacing.

Even after the repair work that I've highlighted, then you're left with all those damaged traces in the battery area - that will be pretty hard to fix without a lot of bodge wires, and even then, it may not work afterwards.

You could use this board to work on, but personally I would recommend you learn/practice with something else first. This is speaking as someone who was in your position 20 years ago, I acquired a IIci and I tried to recap it and bodged it, and actually made it worse, because I didn't practice or spend the time to learn how to solder properly. If I could give my 20 year younger self some advice, it would be to practice, practice, practice on something other than that IIci !