What happens is, after decades of time and heat cycles, the bumper rubber de-vulcanizes and becomes a tar-like substance, glomming onto the armature when it is parked and refusing to let go under the relatively weak power of the armature's voice coil. A small nudge to the armature as soon as the platters are spinning at power-up is enough to break the armature loose and allow the drive to function normally, which it will do indefinitely until the next time the heads are parked.

So there are two models (at least) with this problem: the ProDrive LPS (pictured here) and the ProDrive ELS, which is a slightly different model from around the same era. The primary difference between these two models is that the LPS uses a hybrid servo system that combines an optical grid for coarse positioning with an embedded servo for final track seeking, and the ELS is a faster drive that is entirely embedded servo. The LPS was available between 40 and 230MB, while the ELS started at 40MB and eventually hit 500+MB (they may have changed the name to Lightning and/or Maverick on later drives, and may or may not have changed internals on these later larger drives). I like the LPS because they have a very distinctive sound to them, specifically the thermal recalibration that they perform roughly every 30 seconds whether you're actively moving data on the drive or not.

From what I have seen, the LPS is the easier of the two to service: simply remove the top set of magnets, remove the degraded rubber, replace with new shock-absorbent material*, and reassemble. From then it should work indefinitely, with the only real future failure points being spindle bearing failure or head crashes. I did notice that drives that have been stored in a humid environment will tend to develop corrosion on the top platter directly underneath the breather holes, so you may want to at least store your drives/Macs in sealed bags if they'll be sitting for a while.

The ELS is a different beast: it still has the one bumper on the magnet assembly, but it has another as well: underneath the bottom platter. This lower bumper is what causes the armature to stick. This bumper is also impossible to replace without removing the platters, which is a serious proposition on double-platter drives (the platters must be returned in their original positions relative to each other or the servo data will no longer align and the drive will not function). Single platter drives (40 or 80MB versions) are do-able but it's still a major operation that will likely result in failure unless the utmost care is taken to ensure complete cleanliness of the work area.

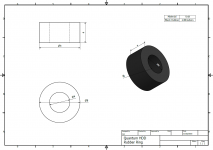

*The shock-absorbent material doesn't have to be rubber per se, but anything that's tough, non-shedding (felt is a no-go) and slightly cushy (hard plastic is a no-go) would work fine. I would probably suggest something synthetic. Also, the specifications of the bumper rubber for both drives appears to be the same or close enough not to matter. With these bumpers you really just need to be roughly the same height and the same or slightly smaller diameter. They don't do anything critical once the drive is operating, however from my experiments I have determined that it is impossible to run a drive without some sort of bumper being in place: with out it, the armature moves too far inward at power-down and the heads scrape on the spindle, which not only contaminates the HDA with particulates but will also result in a catastrophic failure if one of the heads is grabbed by the spindle.