Trash80toHP_Mini

NIGHT STALKER

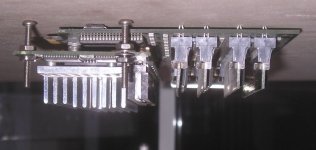

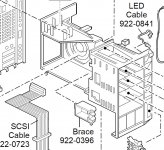

Subject came up when I mentioned the full three slots free installation of a 2/4 HPV card on the floor of my Radius 81/110 Big Metal Can™

@jeremywork asked if the same might be done in his PowerMac 8100 . . . we'll see!

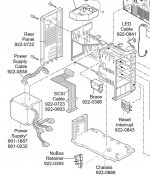

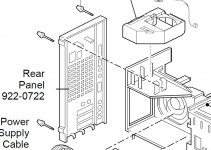

View attachment 30453

Now you've gotten me curious! Is that the same case as the 840AV with a fourth "NuBus" slot panel for the PDS VidCard in place of the "AV panel? of the 840? If such is the case, we've got a good starting place. :approve:

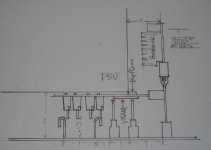

View attachment 30454

Which G3 kit are you using, looks like the Sonnet setup from here? If so you may or may not have a tad less room than the NewerTech setup, but I've got a Sonnet Kit stored away somewhere as well.

Case modifications are required, rough outline of process:

1 - Disassemble case sections.

2 - Remove RFI shielding on the floor of the case. (figuring we'll need to bend the retaining teeth up to get it off the pins)

4 - Figure measurement from edge of router base to back, front and center of slot to be cut in case bottom

__________ add 1 1/2" to each measurement for screwing 1x2" guides for router base on top of template (from bottom)

__________ allow for another 3 1/2" on outboard side for clamps, allows use a piece of 1x4" as a jig for mounting 1x2" router guide on outboard side

5 - Place RFI shielding on top of a piece of 3/8" plywood at the offsets figured above.

4 - Mark centers of back six holes to be drilled in template/router jig for centering it up with router base offsets front back and outboard side

__________ and mark anything else that might need to be removed to prevent router jig from sitting flat on the baseplate section

5 - Drill six holes for registration of jig and drill out or cut away anything else that might be in the way.

6 - Clamp the three guides to jig and use screws from bottom side to hold them in place

7 - Clamp jig onto sacrificial material or use spacers to protect worktop

8 - Use router to cut away section of template covering slot to be cut in bottom of case using a bit wider than final PCB+ thickness of slot in case bottom.

9 - Clamp jig to base unit and set depth of router bit so it removes about half the thickness of the case bottom away

__________ reassemble case (less the RFI plate) to test for fitment

10 - Remove backplane plate from HPV card and have at it! [ ]

]

The Slot will have been set up to hold the card parallel to the MoBo over the NuBus cards at a height matched to cable adapter height. WAG is that the HPV Card/Cable extension assembly fit without going through the bottom of the case. The arrow PCB+ slot will hold it in place vertically. Cable may or may not be pushing that side of card up too high, dunno, may need hold downs attached to PSU support shelf? No biggie there if so.

Is the 8100 board significantly better than the 7100 board if at all different? Can I use my 7100 board, same form factor or at least the slot section matches?

@jeremywork asked if the same might be done in his PowerMac 8100 . . . we'll see!

View attachment 30453

Now you've gotten me curious! Is that the same case as the 840AV with a fourth "NuBus" slot panel for the PDS VidCard in place of the "AV panel? of the 840? If such is the case, we've got a good starting place. :approve:

View attachment 30454

Which G3 kit are you using, looks like the Sonnet setup from here? If so you may or may not have a tad less room than the NewerTech setup, but I've got a Sonnet Kit stored away somewhere as well.

Case modifications are required, rough outline of process:

1 - Disassemble case sections.

2 - Remove RFI shielding on the floor of the case. (figuring we'll need to bend the retaining teeth up to get it off the pins)

4 - Figure measurement from edge of router base to back, front and center of slot to be cut in case bottom

__________ add 1 1/2" to each measurement for screwing 1x2" guides for router base on top of template (from bottom)

__________ allow for another 3 1/2" on outboard side for clamps, allows use a piece of 1x4" as a jig for mounting 1x2" router guide on outboard side

5 - Place RFI shielding on top of a piece of 3/8" plywood at the offsets figured above.

4 - Mark centers of back six holes to be drilled in template/router jig for centering it up with router base offsets front back and outboard side

__________ and mark anything else that might need to be removed to prevent router jig from sitting flat on the baseplate section

5 - Drill six holes for registration of jig and drill out or cut away anything else that might be in the way.

6 - Clamp the three guides to jig and use screws from bottom side to hold them in place

7 - Clamp jig onto sacrificial material or use spacers to protect worktop

8 - Use router to cut away section of template covering slot to be cut in bottom of case using a bit wider than final PCB+ thickness of slot in case bottom.

9 - Clamp jig to base unit and set depth of router bit so it removes about half the thickness of the case bottom away

__________ reassemble case (less the RFI plate) to test for fitment

10 - Remove backplane plate from HPV card and have at it! [

The Slot will have been set up to hold the card parallel to the MoBo over the NuBus cards at a height matched to cable adapter height. WAG is that the HPV Card/Cable extension assembly fit without going through the bottom of the case. The arrow PCB+ slot will hold it in place vertically. Cable may or may not be pushing that side of card up too high, dunno, may need hold downs attached to PSU support shelf? No biggie there if so.

Is the 8100 board significantly better than the 7100 board if at all different? Can I use my 7100 board, same form factor or at least the slot section matches?

Last edited by a moderator: