So here's a build log, perhaps this will help others wishing to do the same:

First thing I did was take the and remove internals of the FSP220 from the casing. I unscrewed the ground lug and desoldered the leads from the power connector (there is no power switch on this model). Don’t mix up the neutral and hot leads, definately mark them somehow. Here it is inside the empty Astec casing for fitment trials:

Yay, it fits! So now lets make a method to screw the PCB to the case. Firstly, bend down the center standoff and make it flat with the case because we wont be using it. Then, use standard PC motherboard standoffs, drilled and screwed into the casing with the same hole pattern as the FSP220 PCB. Make sure to leave the clear insulation sheet in place:

Here is the backside of the casing, showing the PC motherboard standoffs drilled through. The depth was shallow compared to the casings normal standoffs, so there is no clearance issues with stabbing the analog board:

On the original Astec power supply, the PCB and the power switch are connected with a cable. I got the idea to desolder the connector from the old PCB and use it to make a similar plug in cable. First, solder a white (neutral) and a black (power) appropriately gauged wire to the bare leads on the FSP220. (Remember we had desoldered them from the power connector earlier, and didn’t mix them up). After soldering, secure and insulate them with heat-shrink. Now take the other ends of the wire, and attach them to the that desoldered power connector, and insulate them with heat-shrink. The green (ground) wire, I was going to attach to the empty pin, but the original power connector is missing the matching terminal inside. I was going find one to order, but in the end just soldered it directly to the ground lead on the power connector.

Normally, this style of power supply is operated by soft-power. A momentary switch on the computer case issues a latch which the motherboard places on the PS-ON pin of the power supply. Our SE/30 does not have the circuitry to do this, so we need to force the power supply to be on when the switch is on. We do this by shorting the PS-ON pin (green wire) to GND (black wire). After placing the small shunt, the power supply will turn on fully as soon as the power switch is flipped on. You can secure the shunt with a dab of hot glue. Also in this picture you see the connector with red, brown, and orange wires. I left this intact for a couple of reasons which I will explain in just a bit.

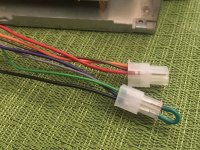

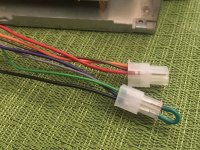

Now we need take the ATX connector from the FSP220 and remove the terminals corresponding to our power requirements. They make a special terminal removal tool, or you can cheap out and use your wife’s flat sewing machine needle. I used yellow/black for the 12v Sweep, yellow for the 12v Drive, blue is -12v, red is 5v, and blacks are ground. Take the old SE-SE/30 connector from the old PSU and remove all the terminals so it is empty. Now because ATX and the SE-SE/30 connector use the same housing, we can directly place the terminals from the ATX connector into the correct ports. I also left a Molex and floppy style connector attached for SCSI2SD power:

Looking at the above picture, everything to the left that’s in the bread tie needs to be removed. The best way to do this is by color. Take everything yellow that you don’t want, and clip them off. Then place some heat-shrink around the bundle of yellow, and fill the top with hot glue. Proceed to the next color. By keeping the colors together, you remove any risk of shorting:

So why didn’t I just recap the existing PCB? It was ruined due to capacitor leakage:

Afterthoughts, notes for next time:

Now that I have a nice terminal crimper, I wouldn’t have removed the terminals from the ATX connector. I would have just lopped it off and put new terminals on the wires I needed. Then, I could have had a shorter cable going from the power supply to the analog board. It’s too long for my liking, but not unwieldy .

I wouldn’t make the little cable to attach the power switch to the PCB. I’d just solder the power leads directly to the switch.

I left the fan installed for a short while, but ended up clipping it completely out. Don't forget to insulate the ends of the wire after clipping it out.

I did this back in December of 2016, and I haven't had a single issue.