Hi,

In terms of the IIcx and IIsi that is correct, they sprayed the inside of the plastics instead of adding a proper EMI shield or faraday case as the iMac G4 uses. The White iMacs use a different kind of shield as well, it is an almost aluminum foil type of material so it varies from machine to machine but all in all I believe these are to prevent radio interference and is typically desirable for electronics and enforced through regulation by the FCC or other bodies in Europe and so on as governed by law. I believe the idea is to prevent the computer from emitting radio frequencies not the other way around. Electronics emit radio frequencies and if all electronics weren't housed inside a shell that prevent the emission there would be a lot of radio signals about and that would cause a lot of problems, especially for highly sensitive instruments such as hospital equipment, this is one of the reasons we are instructed to turn off our electronic devices on take off and landing on an airplane.

Your IIfx should operate as expected even without those EMI shields unless they act as ground somewhere but due to their fragility I would doubt that. I am not an engineer to say this with any confidence but I would imagine the logic board is grounded to the power supply which in turn is grounded to the wall outlet.

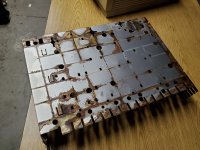

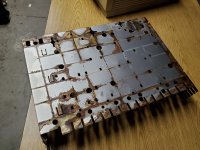

Was the IIfx shielding originally shiny in finish?

For images of the original state of the EMI shielding please open:

https://www.oldcomputr.com/apple-macintosh-iifx-1990/

By the way, some other machines that share the same type of shiny shielding are the 7x00 series Mac all the way up to the Power Mac G3 desktop, the latter I don't own but they all have the EMI shield under the logic board. Other Macs share this material in some cases just around the I/O ports and under logic boards, like the Power Macintosh 8600/9600 towers. I don't know why exactly they are 'tinned' for lack of a better term, it might be to simply prevent corrosion such as rust from developing on an otherwise flimsy piece of metal. It is possible that the proper spray paint contributed to staying with FCC rules on EMI shielding. I couldn't find out if a primer should be applied beforehand. I would contact one of the manufactures first just don't expect them to know what a Macintosh IIfx is, instead send a photo of the part instead, describing that it's for computer shielding.

What I would do in your shoes:

Personally, if I owned a IIfx (my first Mac was a Iix by the way) and I had already gone as far as you have I would be investing in a can of spray paint that is meant to not only protect the shielding but give it the qualities required to behave as intended, in this aspect, to prevent EMI emission - I could be wrong it might actually prevent emission and absorption of unwanted radio signal interference.

To answer your other question, I believe the shielding would put the machine within specifications for hosting a display in top or around the IIfx. After going through the take-apart process it should be clear that this machine was well shielded, especially because it had so much potential for I/O in around and outside the box.

If you think about it, almost every component in a computer, down to ADB, SCSI and other cabling is all heavily shielded.

I would go the extra mile and find an appropriate spray to finish the job just right, that's how I would go forward. Maybe my philosophical bend on restoration can at times be overwhelming even to me because I know that it takes time to do and a project can take days for countless reasons, waiting for parts, waiting for paint or glue to cure, other interruptions or gaps of knowledge etc but it is rewarding to see a machine that once looked pitiful return to its' full or near full glory.

I hope this helps you and encourages you. The IIfx seems to be a rarer find these days so even if it seems like a lot of work, it's worth preserving. This was the top of the line machine way back so not many were manufactured — they weren't cheap!

Some manufacturer's and a description:

Starts with a great description of EMI/RFI shielding.

https://www.vacuum-metalizing.com/industrial-services/rfi-shielding-paint-coatings/

Appears to be a product for the IIsi, cx range as they enjoy a spray coating on the plastic.

https://hollandshielding.com/Electrically-conductive-nickel-coating

https://conformalcoatings.com/materials/rfi-emi-shielding/

Mentioned previously

https://muellercorp.com/the-benefits-of-rfi-emi-spray-coating-for-components/

https://www.mgchemicals.com/products/emi-and-rfi-shielding/

I recommend a google image search for "RFI EMI Aerosol" or "RFI EMI Aerosol high gloss" (without the quotes) and you should land on a product.

The package you want should be an aerosol, if you search for can you might need a brush and that might yield an uneven finish. Even finishes will require spraying.

As a side note, the Quadra 950 actually has a gold colored coating on the inside of the plastic case. I came across a product for that. I typically start with google image searches and work my way backwards.

Cheers!

—Alex