matttintoshplus

Member

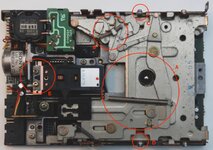

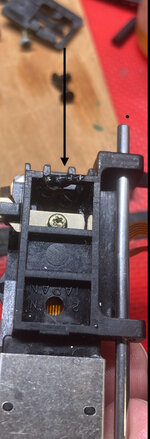

Went to clean my Performa 475 floppy drive and I stretched out the spring. Rookie mistake, I know. Is there a way to re-tighten the spring? Or do I have to find a replacement? If so... anyone know where I can get my hands on one without paying an arm and a leg?

I'm not actually sure if the drive worked to begin with but I'd like to get it up and running. At the very least, I'd like to find a way to transfer files to and from this bad boy without having to buy a hundred-dollar adapter.

Any ideas or advice are more than welcome, thanks

I'm not actually sure if the drive worked to begin with but I'd like to get it up and running. At the very least, I'd like to find a way to transfer files to and from this bad boy without having to buy a hundred-dollar adapter.

Any ideas or advice are more than welcome, thanks