I don't know what's going on with needing so many layers, but I have a couple of suggestions.

First, use the tutorial. I think you did already, but just in case you skipped the bits on routing....

Second, read the specifications for the PCB service you hope to use and set your trace width and trace spacing to match. I believe that Seed Studio allows down 6 mil (6/1000") traces. Signal traces do not need to be any wider than that.

Third, keep the annular rings around your vias small. You can probably make them about 10 mils, (20 mils wider total than the via drill hole) and be okay, although I remember reading some handy guidelines somewhere once.

Fourth, this is more a matter of style, but if you're not using a netlist, first choose your PCB size. Then put your components on the board, generally where you expect them to land. Then use the (connection?) tool to connect the various pins which will connect together. Now you have a rats nest.

Now start routing the traces. When you need to add a via, you'll want to create the via in place, then use one of the tool (forget which one) to connect the via to the rats nest trace. Then cut the trace between one of the pins and the via. The pin should change colors because the netlist still says it should be connected, but it isn't any more. Then switch active layers of the board, and connect the pin and via back up on the other layer. If the pin doesn't exist on both layers, you'll need a second via, of course.

At least that's the way I remember doing it.

Fifth, try to use one layer for horizontal traces and the other layer for vertical traces. Switch between them with vias. This is not a firm rule -- it's down right floppy, but it's a useful state of mind.

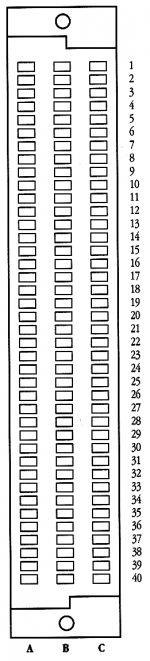

Here's a two layer board I laid out. There are something like 300 pins on both connectors and I put it on 2 layers:

Both:

Front:

Back:

And here's the resulting board:

Didn't work though. That's a two layer board trying to act as a 40 - 50 MHz CPU adapter for the ANS. One of these days, I'll get back to it...

The JPGs are kind of low res. If you like I can upload the Osmond file when I get home tonight. It's about twelve years old, so I'm not certain that the file format is still compatible.

Actually, come to think of it, I have 50 or 60 saved files for this one design, if it hasn't been lost in the hard drive catastrophes over the years. Fifty or 60 saved files, because when I'm laying out circuit board I save often, and always do Save As, so I can revert to an earlier design.

So, my collection of saved files really is a record of the progression of the layout. Would that be helpful?