Hi guys,

follow up notes after replacing the capacitors on the motor board.

Honestly, I could not see any difference between before and after. Either way, the disk drive passed more than 2000 random test units without any fault.

I'm not saying capacitors may not need replacement (I have replaced hundreds of them in my Mac and NeXT systems), but I would personally spare the trouble if not strictly needed. Surface mounted stuff like the ones you can find on SE/30s surely need replacement, but my direct experience is telling me that radial electrolytic are normally OK even after so many years. I only remember one single case where radial electrolytic capacitors miserably failed and caused complete malfunction of the drive and that's about the (in)famous MO drive in the NeXT Computer. For what that matters, I have recapped some of those units too and they all failed in the overheated motor board only, analog boards being normally OK.

Anyhow, pushed by the enthusiasm of this successful story, I took out of the closet a "cold case". Still a M0130 floppy drive (external unit), which did not show any sign of life, except a constant buzz.

Positive thing about the disk utilities integrated in the "Sony Test" unofficial pre-release is that you can really have a very deep insight of what is working and what not.

So, as soon as I tried to read a disk, the unit threw the message: "Cannot step head" (or something similar, don't remember the exact phrasing). Clearly, the step motor was not able to move (should move to track 00 at start up, which it didn't).

So, as the unit was working perfectly with a tested main PCB, I focussed on it and - proceeding from the stepper connector backward - I did a little bit of component swapping between the faulty and a good board and eventually it came out that component Q107 is the culprit.

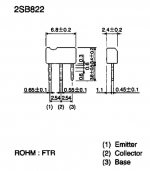

Now, my issue is that I could not find much information about this component, which I'd say must be a diode or transistor of some kind (the back of the board is reading "E" and "B" for the two outermost pins). Component is labelled "B822P M", which so far hasn't lead me anywhere...

Any clue / suggestion?

Thanks in advance!

Paolo

follow up notes after replacing the capacitors on the motor board.

Honestly, I could not see any difference between before and after. Either way, the disk drive passed more than 2000 random test units without any fault.

I'm not saying capacitors may not need replacement (I have replaced hundreds of them in my Mac and NeXT systems), but I would personally spare the trouble if not strictly needed. Surface mounted stuff like the ones you can find on SE/30s surely need replacement, but my direct experience is telling me that radial electrolytic are normally OK even after so many years. I only remember one single case where radial electrolytic capacitors miserably failed and caused complete malfunction of the drive and that's about the (in)famous MO drive in the NeXT Computer. For what that matters, I have recapped some of those units too and they all failed in the overheated motor board only, analog boards being normally OK.

Anyhow, pushed by the enthusiasm of this successful story, I took out of the closet a "cold case". Still a M0130 floppy drive (external unit), which did not show any sign of life, except a constant buzz.

Positive thing about the disk utilities integrated in the "Sony Test" unofficial pre-release is that you can really have a very deep insight of what is working and what not.

So, as soon as I tried to read a disk, the unit threw the message: "Cannot step head" (or something similar, don't remember the exact phrasing). Clearly, the step motor was not able to move (should move to track 00 at start up, which it didn't).

So, as the unit was working perfectly with a tested main PCB, I focussed on it and - proceeding from the stepper connector backward - I did a little bit of component swapping between the faulty and a good board and eventually it came out that component Q107 is the culprit.

Now, my issue is that I could not find much information about this component, which I'd say must be a diode or transistor of some kind (the back of the board is reading "E" and "B" for the two outermost pins). Component is labelled "B822P M", which so far hasn't lead me anywhere...

Any clue / suggestion?

Thanks in advance!

Paolo