well I think the CPu on the Portable is an HC000 which is CMOS. so that entire machine may be CMOS for the power factor.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Macintosh Portable SRAM card: Schematics available?

- Thread starter Stephen_Usher

- Start date

Yeah, the other components were 74AC24x parts. So, I'm guessing the 74HCT parts will be fine then.

As I mentioned, HC is slightly more efficient than HCT if you're interfacing solely with CMOS family parts. HCT should work but there's no reason to prefer it over HC. Is there some part you want that doesn't come in HC?Yeah, the other components were 74AC24x parts. So, I'm guessing the 74HCT parts will be fine then.

Edit: I guess for the record if the parts in the laptop are AC then maybe you should use AC. I'm comparing the datasheet of a 74AC244:

https://www.ti.com/lit/ds/symlink/sn54ac244-sp.pdf

With HC:

https://www.ti.com/lit/ds/symlink/sn74hc244.pdf

And HTC:

https://www.ti.com/lit/ds/symlink/sn74hct244.pdf

And AC is considerably faster. Maybe not enough to matter. Good luck finding an AC '154. ('138s don't look like a problem.)

Last edited by a moderator:

Looking at the spec sheets, there's not a lot of difference between the timing of the 74AC154 and 74HC154 in the worst case. The AC part has a transmission time of between 7ns and 11ns, with 9ns being typical. The HC has a guaranteed 14ns. Removing the 244 would more than compensate for this timing difference.

Is it solely the availability of a ‘154 in HC that’s driving the urge to mix processes? I was serious earlier when I said the ‘154 was considered an obsolete part and had been largely phased out. ‘138s and ‘244s are readily available in any process and if DIP is preferable to you over surface mount I see both in AC at Digikey.

My guess is that, sure, you’ll probably be fine with HC at 16mhz, just pointing out it’s not a necessity to go with non-original if AC is what it has.

My guess is that, sure, you’ll probably be fine with HC at 16mhz, just pointing out it’s not a necessity to go with non-original if AC is what it has.

The 154 is available in plentiful supply from multiple manufacturers and from multiple suppliers. Yes, the AC part is no-longer available but electrically it looks no different to the HC part and the timing change is small (in this context). Having thought about it, both the GAL and the 154 are effectively buffering the address lines, and I wasn't buffering the other lines so I've removed the 244 entirely, which removes a few ns delay. This has massively simplified the design and it's a two chip solution which should fit nicely.

"Obsolete" is a tricky word when it comes to 74 series logic. It's rare for a part to actually stop being manufactured *completely*, but there are parts like the '154 that for whatever reason just don't end up being popular enough to get ported to new processes. That's what I meant. It's available up to HC/HCT, but so far as I can tell they never made it in AC/ACT, VHC/VHCT, etc. Basically, it's not really a part you'd choose for new designs.The 154 is available in plentiful supply from multiple manufacturers and from multiple suppliers.

(Dirty secret: I'm working on something myself that requires a part that's in the same category, IE, still technically manufactured but in a paucity of packages and processes, the 74x670.)

But, anyway, whatever, HC should be fine, and if you're happy with surface mount it's available. And I agree with ditching the '244. If you're hooking CMOS loads straight up to the bus instead of trying to get that LS '154 wedged in there having the '154 and the GAL each sitting on 4 of the address lines adds exactly the same load to the bus as the '244 does, no lines continue on to drive anything else.

Last edited by a moderator:

... Maybe I also have a bit of a vendetta for the '154 because the original .6" wide DIP package of it is genuinely obsolete and costs an arm and a leg now. (It's common in old 8 bit computers and I bought one at one point because I suspected the one in my Commodore PET might be bad. Turned out it wasn't, bad trace, but that was like $6 just for that one old part...)

Last edited by a moderator:

"Obsolete" is a tricky word when it comes to 74 series logic. It's rare for a part to actually stop being manufactured *completely*, but there are parts like the '154 that for whatever reason just don't end up being popular enough to get ported to new processes. That's what I meant. It's available up to HC/HCT, but so far as I can tell they never made it in AC/ACT, VHC/VHCT, etc. Basically, it's not really a part you'd choose for new designs.

(Dirty secret: I'm working on something myself that requires a part that's in the same category, IE, still technically manufactured but in a paucity of packages and processes, the 74x670.)

But, anyway, whatever, HC should be fine, and if you're happy with surface mount it's available. And I agree with ditching the '244. If you're hooking CMOS loads straight up to the bus instead of trying to get that LS '154 wedged in there having the '154 and the GAL each sitting on 4 of the address lines adds exactly the same load to the bus as the '244 does, no lines continue on to drive anything else.

Dang. Since when did you pick up electronics engineering? haha.

Ha! I'd hardly call what I do "engineering". I just decided last year it was time to get off my butt and actually make some stuff myself instead of just shouting from the bleachers, everything I "know" is stuff I picked up in the process.Dang. Since when did you pick up electronics engineering? haha.

The thing I'm working on involving '670s is an EMS RAM controller compatible with the Lo-Tech 2MB card but using a lot less parts. That board needs four 74x573s, a '688, a '138, a '139, a '32, and an '04. My design, which is inspired by this project only needs the two '670s and part of a GAL that's also decoding a conventional memory expansion and an option ROM. GALs are cool.

"Obsolete" is a tricky word when it comes to 74 series logic. It's rare for a part to actually stop being manufactured *completely*, but there are parts like the '154 that for whatever reason just don't end up being popular enough to get ported to new processes. That's what I meant. It's available up to HC/HCT, but so far as I can tell they never made it in AC/ACT, VHC/VHCT, etc. Basically, it's not really a part you'd choose for new designs.

Actually there was a 74AC154 made by Hitachi, which is spec sheet I was getting the timings from. (Best: 7ns, Typical: 9ns, Worst: 11ns) I guess that they didn't bother continuing as circuits would have to assume the worst case, which is only 3ns faster than the HC part and that guarantees 14ns.

Anyway, I'm learning a heck of a lot from this project!

I must admit that I was very surprised that there was an off-the-shelf product which did most of the work.

The SIOC-24 SMD 74HC154 chips are currently available from both of the UK chip suppliers, both the Nexperia and TI versions are ~66p + sales tax.

It's also available as a TSSOP part.

It's also available as a TSSOP part.

Last edited by a moderator:

That must be one rare bird, given Digikey doesn't even list it as an obsolete part (they're pretty good about telling you "yeah, this existed but we don't have it). And I can't find anyone, not even on Aliexpress, claiming to have it for sale. Not to get conspiracy-theory-y but I wouldn't rule out the possibility Hitachi went ahead and made a datasheet for the part but either nobody *ever* ordered it or it was essentially a one-off for one big customer.Actually there was a 74AC154 made by Hitachi, which is spec sheet I was getting the timings from.

I couldn't even find that datasheet on alldatasheet.com, which usually has everything. Eventually found it on datasheets360.com and it looks like a scan from an oooold paper catalog. (Look at the page numbers.) Seriously wouldn't rule out that this came from the process-release databook and was either complete vaporware or rapidly discontinued after an initial batch.

The thing to remember about the HC process is it dates back to early 1980s, verses late '80s for AC, so, again, my point still stands that '154 is technically an obsolete part so far as being carried forward into modern processes. (This page has a quick rundown as to when the various families were introduced and typical delay times for what is probably the simplest part in the 74xx family tree, the 7400 NAND gate.)The SIOC-24 SMD 74HC154 chips are currently available from both of the UK chip suppliers, both the Nexperia and TI versions are ~66p + sales tax.

Frankly I don't know who makes these decisions because clearly a 4-16 decoder is a plenty useful part to have, but for whatever reason it's consigned to the slow parts bin. If I had to hazard a guess... remember how I mentioned that it was a popular part in early 8-bit computers? Embedded designs using derivatives of 1970's CPUs are still being made, for some low-production thing like, I dunno, an elevator controller or building security system that's not worth making an ASIC for a TSSOP 74HC154 that lets you use the same schematic you came up with in 1981 on a smaller board may well make enough economic sense to justify repackaging the old silicon in the smaller carrier.

Last edited by a moderator:

Thanks for the link, very interesting, especially the capacitor part. I may need to add a couple to the circuit, or use the one provided on the main circuit board provided for the VSLI chip.

Oh, yeah, good catch. You should be fine with a 10-100nf (I use .1 picofarad by default, which is a 100nf) placed near the VCC input on each chip between VCC and ground.Thanks for the link, very interesting, especially the capacitor part. I may need to add a couple to the circuit

These are important; on one of the vintage computer forums someone was complaining about getting really unreliable performance from a knock-off of one of the lo-tech XT expansion boards they'd gotten off eBay, and someone pointed out that whoever made it had copied the schematic onto an awesome-looking custom-colored circuit board but had omitted all the decoupling caps.

This is going to be tricky to route on such a 2 layer board.

Why? You have a VCC connection to each pin, you literally just have to drop the capacitor right next to the chip, run a short trace to the VCC pin, and connect ground to the ground pour.This is going to be tricky to route on such a 2 layer board.

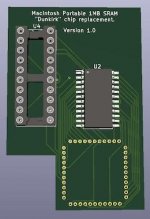

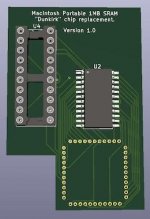

Edit: Judging from the render of your board It looks like you're using Kicad to lay this out? That's what I use. Are you familiar with the "add filled zones" function? Since you don't have a whole layer to dedicate to a "ground plane" in just two layers it's generally standard practice to make a closed shape to the borders of the board on at least the bottom layer connected to the GND net. This will fill all the spaces not occupied by traces with copper (or, technically, it'll tell the PCB house not to etch it away, which is actually better for them) and make it contiguous with the ground pins on every IC. You can do the same on the top, although there seems to be something of a holy war whether it's better to put ground on both sides or make the bottom ground and the top VCC. In either case if you keep VCC on the upper layer it means that dropping in a decoupling cap is trivial unless the traces in an area are incredibly dense.

Last edited by a moderator:

If you want to talk agonizing routing jobs here's that project I've been working on. I just finished the bulk of the routing a couple days ago, I'm basically sitting on it for a few days before sending it off to make sure I'm done having "OMG, I totally forgot about... !!!!" moments or other second thoughts. (There have been several so far.)

There are two decoupling-related things of note here:

1: I'm not proud of it but one chip in the middle there is essentially sharing decoupling with its two neighbors because there's such a dense crossroads of traces there I can't find a place to land a through-hole capacitor. I think I might get away with it, but if I run into problems I can't pin on anything else I'll tack a cap between its VCC and ground pins on the other side, stuff like that is what prototypes are for.

2: Space is at such a premium near the memory chips (the big sockets) that I've put the caps *under* them instead of next to them.

If the circuitry on this is prototyping works it might get redone as surface mount so I can use denser RAM chips. I still need to get over my fear of trying to solder TSOP-II, so, one thing at a time.

There are two decoupling-related things of note here:

1: I'm not proud of it but one chip in the middle there is essentially sharing decoupling with its two neighbors because there's such a dense crossroads of traces there I can't find a place to land a through-hole capacitor. I think I might get away with it, but if I run into problems I can't pin on anything else I'll tack a cap between its VCC and ground pins on the other side, stuff like that is what prototypes are for.

2: Space is at such a premium near the memory chips (the big sockets) that I've put the caps *under* them instead of next to them.

If the circuitry on this is prototyping works it might get redone as surface mount so I can use denser RAM chips. I still need to get over my fear of trying to solder TSOP-II, so, one thing at a time.

Last edited by a moderator:

That's a rather big project. As for TSOP.... eek! I guess paste, mask and a heat gun or oven is the only way to reliably do those. Far easier to do that on a new board without any other components on there.

What caps are you using? Those are smaller than the ones I could see on RS... but there were too many choices anyway.

What caps are you using? Those are smaller than the ones I could see on RS... but there were too many choices anyway.

There's videos of people hand-soldering TSOP-II (and even smaller) with a plain old iron and some desoldering braid, so it's apparently *possible*, but, yeah, eek, .8mm pitch is kind of scary. There's another project I have in the planning stage that requires a 100 pin quad package with .65mm pitch, I have a tube of the chips on the shelf mocking me. For those I think one of the oven techniques is my only shot. On the bright side if I *can* make that work since these are new-build boards would be able to do the oven thing for the surface mounts first and then do everything else by hand.

The caps are plain ceramic disks, .1 pf. They do come in a hideous variety of sizes. In Kicad I'm using the "Capacitor_THT:C_Disc_D3.4mm_W2.1mm" footprint and it's worked with several different physical sizes. (I generally try to give at least some money to my local electronics shop by buying whatever they have over the counter.) Just don't get the ones that come with the leads pre-splayed to fit a wider footprint.

The caps are plain ceramic disks, .1 pf. They do come in a hideous variety of sizes. In Kicad I'm using the "Capacitor_THT:C_Disc_D3.4mm_W2.1mm" footprint and it's worked with several different physical sizes. (I generally try to give at least some money to my local electronics shop by buying whatever they have over the counter.) Just don't get the ones that come with the leads pre-splayed to fit a wider footprint.

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 17

- Views

- 3K