I’m back with another SE/30 repair. I’m hoping that I’ll be able to resurrect this one, as I failed and had some outside help to fix up the last one that had some nasty cap goo trace damage.

This one’s a battery bombed unit, but it was fairly light. It seems it was luckily stored on its face or upside down as the majority of the battery acid rusted the chassis.

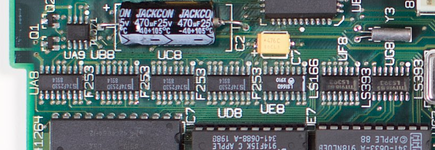

I stripped out all the caps, no lifted pads. I scrubbed it clean, removed the two diodes near the clock chip and the crystal, replaced them, placed new caps down. Also scrubbed the legs of UJ2, UJ3, and UJ4. Legs look intact, but the pads are suspect.

Currently, it’s giving simasimac pattern and death chimes after a short bit. As I understand that behavior, and as those chips are most suspect, this is down to an issue of RAM access.

So, I’ll be looking to lift those chips and clean the pads, check the legs much closer, and then hopefully that wraps up this project.

But I’ve not lifted a chip like this yet in my repairs. I can’t get solder to stick to them at all, so they’re clearly still corroded. I can just replace them, DigiKey has parts but I’d like to try and see if I can work with what’s here first.

I have a good iron and a hot air station to work with along with all the flux, solder and braid I’ll need to get this done. Just looking to solicit some advice on getting those chips off as safely as I can.

Thank you!

Bonus request: Can I soak the whole board in something to help clean up some minor corrosion on the RAM and ROM sockets? And some other spots. I’ve scrubbed where I can but it’s a bit unsightly. I’ll have a gallon of evapo rust tomorrow to work with.

This one’s a battery bombed unit, but it was fairly light. It seems it was luckily stored on its face or upside down as the majority of the battery acid rusted the chassis.

I stripped out all the caps, no lifted pads. I scrubbed it clean, removed the two diodes near the clock chip and the crystal, replaced them, placed new caps down. Also scrubbed the legs of UJ2, UJ3, and UJ4. Legs look intact, but the pads are suspect.

Currently, it’s giving simasimac pattern and death chimes after a short bit. As I understand that behavior, and as those chips are most suspect, this is down to an issue of RAM access.

So, I’ll be looking to lift those chips and clean the pads, check the legs much closer, and then hopefully that wraps up this project.

But I’ve not lifted a chip like this yet in my repairs. I can’t get solder to stick to them at all, so they’re clearly still corroded. I can just replace them, DigiKey has parts but I’d like to try and see if I can work with what’s here first.

I have a good iron and a hot air station to work with along with all the flux, solder and braid I’ll need to get this done. Just looking to solicit some advice on getting those chips off as safely as I can.

Thank you!

Bonus request: Can I soak the whole board in something to help clean up some minor corrosion on the RAM and ROM sockets? And some other spots. I’ve scrubbed where I can but it’s a bit unsightly. I’ll have a gallon of evapo rust tomorrow to work with.