Okay, so I'm an idiot. Turns out probe sensitivity matters a lot. Lesson learned.

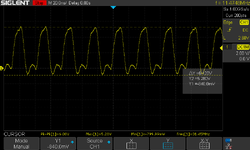

By switching from 1X to 10X, the picture becomes much clearer.

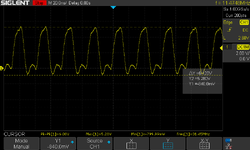

Y2 output:

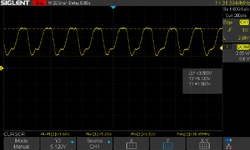

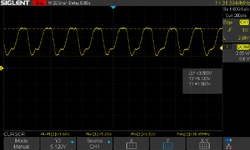

C32M:

So the replacement oscillator Y2 is indeed putting out a full 0-5V swing. It overshoots a bit, but that seems fine?

The real issue is C32M. It's not dropping below 1.5V. So that still points to UH7 as the culprit. Or UI6. Or the GLUE chip (unfortunately not socketed). Those are the only places I can find connected to C32M.

Will I need to source and program a new EEPLD?

By switching from 1X to 10X, the picture becomes much clearer.

Y2 output:

C32M:

So the replacement oscillator Y2 is indeed putting out a full 0-5V swing. It overshoots a bit, but that seems fine?

The real issue is C32M. It's not dropping below 1.5V. So that still points to UH7 as the culprit. Or UI6. Or the GLUE chip (unfortunately not socketed). Those are the only places I can find connected to C32M.

Will I need to source and program a new EEPLD?

Last edited: