Hello everyone,

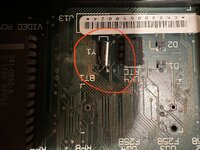

I found a Macintosh SE/30, removed the motherboard, cleaned it, and then tried to turn it on. Here is the result. Can any experts diagnose, or at least isolate, the problem from this symptom? I have read various things about simasimac, but it seems to be a different pattern.

Could it just need a recap, or...?

No chime at start-up.

I found a Macintosh SE/30, removed the motherboard, cleaned it, and then tried to turn it on. Here is the result. Can any experts diagnose, or at least isolate, the problem from this symptom? I have read various things about simasimac, but it seems to be a different pattern.

Could it just need a recap, or...?

No chime at start-up.