So today I decided to try baking an lcd on a parts PowerBook 180 I have.

Used the "warm" setting of 175 for 4 hours. I did not bake it with the circuit board. I straightened the bent tabs fastening the glass sandwich to the backlight and circuit board.

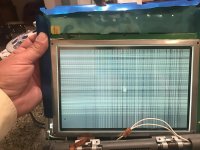

After a decent cool down period I reassembled and tested the lcd. As I feared, lots of vertical black lines and a white ghost outline of the mouse pointer and question mark disk icon.

I took it apart again, tried again and similar but different pattern wise results.

Before the third time I noticed that there are cross hairs on the circuit board and tiny square etched on one of the glass layers. I figured that they are alignment witness marks and did my best to line everything up and ...

Same same. Probably better but not right.

Has anyone successfuly reassembled their active matrix display? Everything draw okay? How did you line everything up right? Are those witness marks?

I understand that I could have baked it attached to the circuit board, but if it was a really successfull bake, I'd want to be able to reseal the glass edges and for that it HAS to come off the board.

Thanks!

Used the "warm" setting of 175 for 4 hours. I did not bake it with the circuit board. I straightened the bent tabs fastening the glass sandwich to the backlight and circuit board.

After a decent cool down period I reassembled and tested the lcd. As I feared, lots of vertical black lines and a white ghost outline of the mouse pointer and question mark disk icon.

I took it apart again, tried again and similar but different pattern wise results.

Before the third time I noticed that there are cross hairs on the circuit board and tiny square etched on one of the glass layers. I figured that they are alignment witness marks and did my best to line everything up and ...

Same same. Probably better but not right.

Has anyone successfuly reassembled their active matrix display? Everything draw okay? How did you line everything up right? Are those witness marks?

I understand that I could have baked it attached to the circuit board, but if it was a really successfull bake, I'd want to be able to reseal the glass edges and for that it HAS to come off the board.

Thanks!