Mustermann

Well-known member

Dear all,

I am currently starting to recap my LC475 main board, right in time as neiter battery nor caps are leaking yet.

It is already decided that I will use ceramic capacitors.

As I am able to order them in 20x lots I am thinking about to replace all of them by 100µF 50V.

As long as they are in +5V, +12V or -5V this should be ok.

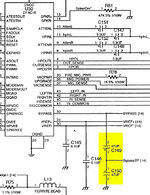

But there are two 47µF capacitors I have no clue what they are doing: C149 and C150.

They are connected in a row to "Bypass" pin of DFAC-II and ground and two testing points.

Does anyone know, what "Bypass" is doing and if these capacitors can be changed into 100µF?

Best regards,

Mustermann

I am currently starting to recap my LC475 main board, right in time as neiter battery nor caps are leaking yet.

It is already decided that I will use ceramic capacitors.

As I am able to order them in 20x lots I am thinking about to replace all of them by 100µF 50V.

As long as they are in +5V, +12V or -5V this should be ok.

But there are two 47µF capacitors I have no clue what they are doing: C149 and C150.

They are connected in a row to "Bypass" pin of DFAC-II and ground and two testing points.

Does anyone know, what "Bypass" is doing and if these capacitors can be changed into 100µF?

Best regards,

Mustermann