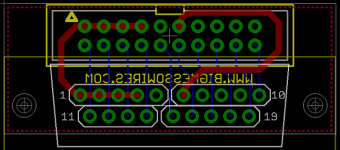

OK, I have a couple of little PCBs here that I think could work as a DB19 substitute. I decided to forget about the shield, and instead I added holes where the mounting screws normally go, so you can visually see from behind whether the connector is aligned properly. If somebody still messes it up, well, too bad.

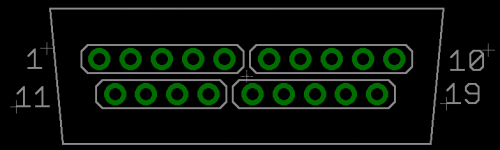

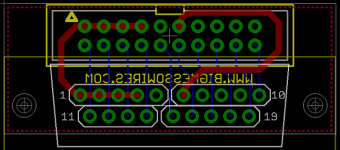

The first one uses the footprint I posted above, relying on slight bending in four sections of standard 0.1 inch header. Then it's got a standard IDC-20 header above that, where you can plug in a cable. The whole thing has to be very tiny in order to fit the recessed area around the I/O ports on the Mac 128K and 512K.

The second one (not pictured) is basically the same as the first, except the holes are exactly on a standard D-SUB pitch of 2.77mm. Then you can put 19 individual D-SUB crimp pins in the holes, solder them, and cut off the crimp part of each pin. It would be more awkward and expensive to assemble, but would give a better fit and might be more reliable in the long-term than bendy square header pins. I'm going to talk to the assembly guys I use and ask how much of a pain this would be to assemble.

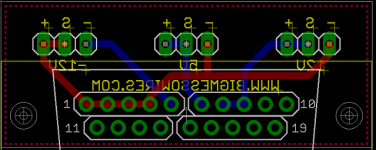

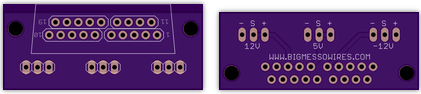

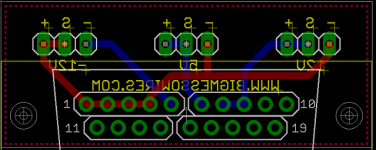

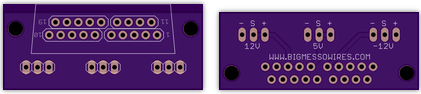

I also used the first footprint to make you a PCB for your power meter. This is basically the thing you asked me about over email that I said I wasn't going to do.

It's got minus, sense, and plus broken out for each power rail. The lines are swapped for the -12V supply. You can send these Gerbers to Seeed or somebody if you want to get boards made.

power-meter-gerbers.zip

power-meter-eagle-files.zip

power-meter-gerbers.zip

power-meter-eagle-files.zip