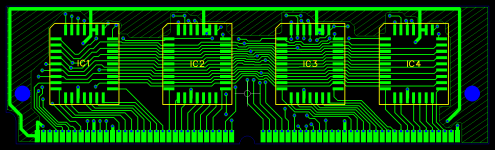

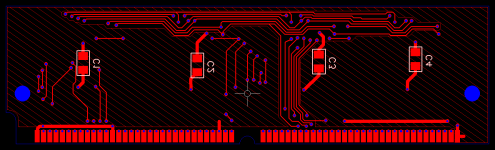

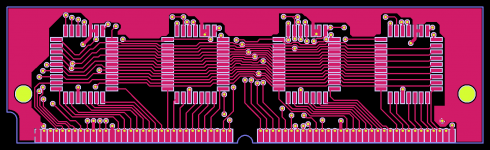

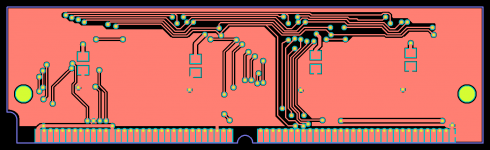

No schematic for my design. I usually do what amounts to a netlist on the fly. After I've created the parts in Osmond, I connect all the pads that need connecting, which results in what's called a Rat's Nest.

You can't see it on the images I captured, but the edge connector for the ROM is a Part, and the PLCC32 chips are Parts, and there's a view mode in Osmond which will show the pin numbers (and names, if you've entered them). That view mode is pretty handy for creating the Rat's Nest.

Once the Rat's Nest is created, it's just a matter of dragging the traces all over the place, until you meet the design rules. Of course, one ends up pushing some of the traces through vias, and that is a little more complicated than dragging a trace, but Osmond remembers what's supposed to make electrical connections, so it's pretty easy to cut a trace on one side of the board and see where to pick it up on the other side.

Of course, one ends up pushing some of the traces through vias, and that is a little more complicated than dragging a trace, but Osmond remembers what's supposed to make electrical connections, so it's pretty easy to cut a trace on one side of the board and see where to pick it up on the other side.

You can't see it on the images I captured, but the edge connector for the ROM is a Part, and the PLCC32 chips are Parts, and there's a view mode in Osmond which will show the pin numbers (and names, if you've entered them). That view mode is pretty handy for creating the Rat's Nest.

Once the Rat's Nest is created, it's just a matter of dragging the traces all over the place, until you meet the design rules.