My primary goal is to have a working internal high density floppy drive "SuperDrive" on a Macintosh SE/30. I'd appreciate any thoughts about my situation.

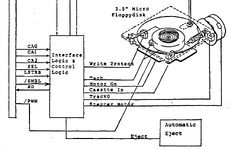

I received two 3.5" DSHD (FDHD) floppy drives, both Sony MP-F75W-01G floppy drives. One came out of the very SE/30 I'm working with. They were filthy and non-working and that prompted me to perform cleaning, re-greasing, and recapping (Console5 kits). It turned out that both floppy drives' original capacitor values measured mostly okay, and also the original worm mechanism gears were fine. I took some notes about the process.

Both drives do NOT read or initialize 3.5" DD or HD media in the SE/30 running System 6.0.8 or 7.5.5 with a 32-bit clean ROM (if the software environment makes any difference).

The Mac SE/30 I'm working with was formerly simasimac and was professionally repaired and tested by a service. The memory and ROM are new. It's running off of a plain Pico-based BlueSCSI. These are just notes, there's been no other issues with the computer.

The floppy disk media I'm working with fully functions (initializes, reads, and writes) in an external Apple 3.5 Drive (A9M0106) on the same Mac. The external drive will recognize and format my DD and HD disk media just fine. I thought this was only a DD drive, but HD seems to also work when on this controller. If I put these same disks in either Sony MP-F75W-01G, the computer prompts that it needs to initialize them. After running through that process it says that the disk is bad and ejects it. Putting that same disk back in the external drive shows it hasn't been touched and that there are still valid files and programs. There's truly no read or write happening on these Sony drives. I have tried two different floppy cables.

I read some posts on here about the UH7 SWIM chip. But if that component were bad, I think that the external drive also would not work? Adding a 2pF capacitor to the PCB as an experiment made no difference.

I took some videos of the Sony drives:

On eBay the external drives seem to be much cheaper than internal ones. Would parting out an external work as compatible substitute? I don't want to take apart the working external I already have.

I'll see about finding another Mac that takes FDHD to also try these in if that would help narrow things or not.

Would it help to find or buy a third auto inject drive to compare against these two?

I received two 3.5" DSHD (FDHD) floppy drives, both Sony MP-F75W-01G floppy drives. One came out of the very SE/30 I'm working with. They were filthy and non-working and that prompted me to perform cleaning, re-greasing, and recapping (Console5 kits). It turned out that both floppy drives' original capacitor values measured mostly okay, and also the original worm mechanism gears were fine. I took some notes about the process.

Both drives do NOT read or initialize 3.5" DD or HD media in the SE/30 running System 6.0.8 or 7.5.5 with a 32-bit clean ROM (if the software environment makes any difference).

The Mac SE/30 I'm working with was formerly simasimac and was professionally repaired and tested by a service. The memory and ROM are new. It's running off of a plain Pico-based BlueSCSI. These are just notes, there's been no other issues with the computer.

The floppy disk media I'm working with fully functions (initializes, reads, and writes) in an external Apple 3.5 Drive (A9M0106) on the same Mac. The external drive will recognize and format my DD and HD disk media just fine. I thought this was only a DD drive, but HD seems to also work when on this controller. If I put these same disks in either Sony MP-F75W-01G, the computer prompts that it needs to initialize them. After running through that process it says that the disk is bad and ejects it. Putting that same disk back in the external drive shows it hasn't been touched and that there are still valid files and programs. There's truly no read or write happening on these Sony drives. I have tried two different floppy cables.

I read some posts on here about the UH7 SWIM chip. But if that component were bad, I think that the external drive also would not work? Adding a 2pF capacitor to the PCB as an experiment made no difference.

I took some videos of the Sony drives:

On eBay the external drives seem to be much cheaper than internal ones. Would parting out an external work as compatible substitute? I don't want to take apart the working external I already have.

I'll see about finding another Mac that takes FDHD to also try these in if that would help narrow things or not.

Would it help to find or buy a third auto inject drive to compare against these two?