Picked up a new Quadra 605 off the free table at VCFMW, and it's inspired me to finally make some ABS case repair pieces for the awful brittle fire retardant ABS these cases are made out of.

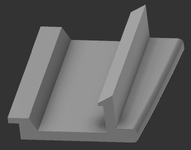

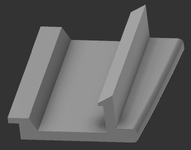

First up a replacement case tab. Modeled for the left side, but just mirror it in your 3D printing software if needed. Recommend printing it on edge. File down the broken bit as seen below until it's flat an all remains of the tab have been removed. Then use acetone to fuse the mating surfaces.

Make sure the catch part of the tab is a sharp 90, also - it may benefit from some filing if your printer rounded it a bit. Hatchbox beige abs doesn't match aged plastic well, it seems.

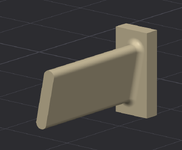

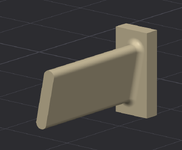

Next are LB retention tabs. Use a dremel to reduce the remains of the tab flat (as seen in third pic), apply acetone to both case and part then stick them together. Take some care to get the alignment right - the right tab (near psu) just needs to be straight in the cutout of the shielding, the leftside tab is offset towards the center slightly.

Designed for the leftside, mirror in your 3D printing software if required. STRONGLY recommend printing with below orientation with supports enabled as this means the sometimes problematic layer adhesion of ABS isn't on the flexing axis.

Bonus: for the broken heat-stake plastic circles holding the RF shielding, remove the broken remains, align the shielding where it ought to be, then use a hot glue gun to inject glue leaving a small bubble on the surface. Similar to what was originally done but using hot glue.

First up a replacement case tab. Modeled for the left side, but just mirror it in your 3D printing software if needed. Recommend printing it on edge. File down the broken bit as seen below until it's flat an all remains of the tab have been removed. Then use acetone to fuse the mating surfaces.

Make sure the catch part of the tab is a sharp 90, also - it may benefit from some filing if your printer rounded it a bit. Hatchbox beige abs doesn't match aged plastic well, it seems.

Next are LB retention tabs. Use a dremel to reduce the remains of the tab flat (as seen in third pic), apply acetone to both case and part then stick them together. Take some care to get the alignment right - the right tab (near psu) just needs to be straight in the cutout of the shielding, the leftside tab is offset towards the center slightly.

Designed for the leftside, mirror in your 3D printing software if required. STRONGLY recommend printing with below orientation with supports enabled as this means the sometimes problematic layer adhesion of ABS isn't on the flexing axis.

Bonus: for the broken heat-stake plastic circles holding the RF shielding, remove the broken remains, align the shielding where it ought to be, then use a hot glue gun to inject glue leaving a small bubble on the surface. Similar to what was originally done but using hot glue.