Oh man, jt is starting to have an identity crisis...

Once more, gang, it's Trash or jt (in LOWER case) or I get confused about who I am . . .

Once more, gang, it's Trash or jt (in LOWER case) or I get confused about who I am . . .

I dunno why he's rambling about this, tbh. I've addressed him as JT in other posts, and in PMs, and he's never made a stink about it. I figure just as long as you don't address him by his full username, you should be OK.Oh man, jt is starting to have an identity crisis...

thanks

JT

/fun-n-games!THX, bro, I needed a laugh!

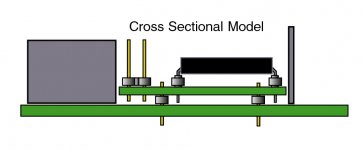

Um... What? I'm not sure what you mean by conversion PCB. AFAICT from the drawing above, you're talking about making a ROM SIMM that takes DIP sockets instead of PLCC?@ dougg3 & bbraun: will the conversion PCB for the ROM SIMM help to increase the size of the Addressable ROM space or just make it possible to use the ROM SIMM for ROMswappin-n- hackin' the Compact series . . . or neither?

I use an AEK-1 with an iMate as my keyboard at work.anyone here use a AEK-II /w adb2usb as an every day kbd?

I am no expert, but I am guessing if the trace lengths are different say on the order of 1-2cm, there will be no impact to the timings, etc., hence no need to worry about them. The main thing is having a schematic and ready-made parts available in a standard library (if using Eagle CAD). If those are available in Eagle CAD, which they probably are, then making that design would not be too difficult.@tt: how critical do you think trace length will be for my PCB IC->50 pin IDC header Adapter? I'm going to try counting the tick marks on dashed lines in AI to roughly equalize trace lengths, then have someone do a "real" PCB layout for seeeding some boards.

You have gone way beyond that so far though... Get a nice rainbow ribbon, solder the wires and you are done. It can have a male socket at the other end if you want it connectorized.K.I.S.S. live by it!//