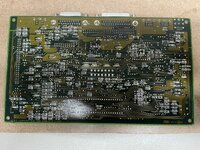

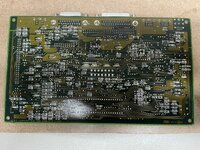

Hello folks! I'm working on bringing my college 1991 Macintosh Classic back to life. It suffered from leaking capacitors and was completely dead, so I decided to learn how to solder and did a complete recap of both the logic and analog boards and a through cleaning with 99% iso. After some reflowing of my amateurish soldering it came back to life in all regards except one - a complete lack of audio. At this point I am stuck. I have checked the speaker (resistance 61.5 ohms), tried using headphones (no sound), and desoldered, cleaned, and resoldered the UA5 sound chip twice. I cannot see any broken traces - is the sound chip simply dead? I am new to this, so any advice would be most welcome! I am attaching some photos of the logic board as it currently sits.

Many thanks!

Otho

Many thanks!

Otho