@Trash80toHP_Mini if you need an LC to play around with I think I have some, they work but need caps. I'm sure I can lend one out if you think it would be helpful.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Farallon ETHERMAC LC NSC w/NuBus drivers in the SE/30 PDS?

- Thread starter Trash80toHP_Mini

- Start date

Thanks for the offer. I've got a pair of DOA LCs I mostly got for hacking the case lids long before the caps issue came to the forefront. They may be good after all?

Popped the lid on one and it's PDS is well marked on the silk screen layer. Checked the DOA SE/30 board (got it in trade from someone who borked it in a recap attempt) is marked the same manner. Never realized there was a "Mirrored Z" patterned number scheme for the pins from pin 1 @ 1A to pin 32 @ A32, then over to pin 33 @ B32 and back from there pin 64 @ B1 and finally over to pin 65 @ C1 and up to pin 96 @ C32. 68030 PDS is the same deal with 120 pin. Always bothered me that the columns weren't labeled A-B-C for grid reference on the boards, but now I know how it's done. [ ]

]

Spudged the wrap map from the connector side with the help of a top coat of it as a solvent. Which bring a question to mind:

Does anyone know if Elmer's Rubber Cement is at all conductive or a good insulator? Figured it'd be the latter, but now I have need to know.

Popped the lid on one and it's PDS is well marked on the silk screen layer. Checked the DOA SE/30 board (got it in trade from someone who borked it in a recap attempt) is marked the same manner. Never realized there was a "Mirrored Z" patterned number scheme for the pins from pin 1 @ 1A to pin 32 @ A32, then over to pin 33 @ B32 and back from there pin 64 @ B1 and finally over to pin 65 @ C1 and up to pin 96 @ C32. 68030 PDS is the same deal with 120 pin. Always bothered me that the columns weren't labeled A-B-C for grid reference on the boards, but now I know how it's done. [

Spudged the wrap map from the connector side with the help of a top coat of it as a solvent. Which bring a question to mind:

Does anyone know if Elmer's Rubber Cement is at all conductive or a good insulator? Figured it'd be the latter, but now I have need to know.

So many capacitor issues, seems to be the bane of the hobby. Interesting question about Elmer's rubber cement. I, of course, could not answer that. I would *think* it would be a good insulation rather than conductive.

Plop some down on a piece of paper, let it cure, and test it with a multimeter. But I highly doubt that it will be conductive.So many capacitor issues, seems to be the bane of the hobby. Interesting question about Elmer's rubber cement. I, of course, could not answer that. I would *think* it would be a good insulation rather than conductive.

Figured that wasn't definitive for testing logical level shortages when contaminants might be involved. Now I remember I might have found my preferred can of 3M Super 77 spray adhesive for application #2. Didn't think things all the way thru or do my usual level homework error check/editing in my haste to get to the wrapping.

Worst possible case would be a fresh start with a new board on hand, not crazy about reliability issues of a 1/2 to 3/4 level wrap on soldertail pins when it comes to stripping all the wires on one end while wrapped at the other. Tending toward re-boot ATM, practice makes perfect, no? : Might even be faster when done more methodically than doing re-work.

Might even be faster when done more methodically than doing re-work.

Worst possible case would be a fresh start with a new board on hand, not crazy about reliability issues of a 1/2 to 3/4 level wrap on soldertail pins when it comes to stripping all the wires on one end while wrapped at the other. Tending toward re-boot ATM, practice makes perfect, no? :

Last edited by a moderator:

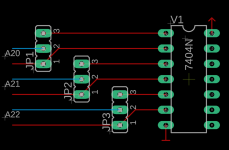

@Bolle How about that jumper modified address inversion circuit diagram/wrap map layout in PCB format for $9 and $A? Impending Monday arrival of wire wrap sockets for my Mon-Tue weekend allows wrapping that circuit form right from the start and doing a temporary straight connection for research on a second wrap level on proper wire wrap pins for later removal. While waiting arrival of a proper assortment of ICs to be sourced after you come up with some alternate specs I can get er' done the right way.

Kit's packed up for stripping it all off for a fresh Perf Board reboot in down time at work tonight. Here we go again! :lol:

This time pin key only is going on the adapter with 77 and the integrated wrap map and logic schematic will be on cardboard bolted up to the solder sides of NIC and SuperMac adapter to in iterative layers keep it all together well enough for posterity. :approve:

Kit's packed up for stripping it all off for a fresh Perf Board reboot in down time at work tonight. Here we go again! :lol:

This time pin key only is going on the adapter with 77 and the integrated wrap map and logic schematic will be on cardboard bolted up to the solder sides of NIC and SuperMac adapter to in iterative layers keep it all together well enough for posterity. :approve:

Last edited by a moderator:

Wrap sockets for the logic just arrived at the rental office! [ ]

]

Sweet. That'll cover both $9 and $A? inversions? How should I document the jumper settings on the board? Can I leave the unused inverter's lines floating? Doesn't look like it's be a problem from the diagram of the 04, but may it be a "best practices" kinda deal to nail them to ground?

Tie the remaining inputs to ground if you want to do it by the book, it shouldn't matter though.

If you put a jumper between 1+2 you will get the normal non-inverted address line.

Putting a jumper to 2+3 inverts that address line.

For $9 you invert only A22, for $A you invert all three lines. Of course you will have to wire up the interrupt accordingly to the address inversion you choose. Could add an other jumper for that or do it by hand.

If you put a jumper between 1+2 you will get the normal non-inverted address line.

Putting a jumper to 2+3 inverts that address line.

For $9 you invert only A22, for $A you invert all three lines. Of course you will have to wire up the interrupt accordingly to the address inversion you choose. Could add an other jumper for that or do it by hand.

Last edited by a moderator:

Thanks, I'll get the graphic set up in the new board key. I've got the address lines jumpers set up and documented already. I'll be posting a new wrap map diagram for error checking tonight.

@maceffects I'll include instructions on how to check its accuracy. You don't need to know anything about the signals themselves. It's but a comparison of the grid locations from the LC side to the table, reading off the mapped grid location from the table and checking that grid location on the 030 side to make sure the text matches the text on the grid location where you started.

It's The Imitation Game of PDS association. [ ]

]

@maceffects I'll include instructions on how to check its accuracy. You don't need to know anything about the signals themselves. It's but a comparison of the grid locations from the LC side to the table, reading off the mapped grid location from the table and checking that grid location on the 030 side to make sure the text matches the text on the grid location where you started.

It's The Imitation Game of PDS association. [

@Trash80toHP_Mini Sure, I'd be happy to help check connections if you can give me detailed instructions as to what I would need to do. Likewise, if this one works, I'd like to wire wrap and test the SE version using the prototyping card I have for that machine.

@Bolle That looks great, a good solution. I'm always amazed to see what can happen when a couple of really intelligent hobbyists.

@Bolle That looks great, a good solution. I'm always amazed to see what can happen when a couple of really intelligent hobbyists.

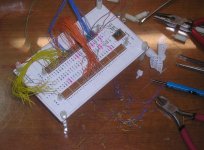

From this:

to this:

32 Data lines left to unwrap and clip, but I'm gonna miss the luscious loopiness of the FUBAR version. :mellow:

Address(Yellow) and Control (Blue) lines will wind up looking much like the straight across the board loop of the Data (Orange) lines that have yet to be unwapped for correction when wrapped to the proper end of the 030 PDS. Decided I can strain relief the bundles and strip in place so I won't have to start over with a new PCB. I'll work around my adhesive contaminant concerns with liberal application of larger drill bits or adding one of the small prototyping cards on hand into the mix as a daughtercard. Leaning toward the latter. Bit of good news though, the jumpered address line length is much reduced so shortening everything up will still keep the traces "meandered" and easily reworked. I'm almost tempted to go ahead and solder the wraps columns A & C on the LC side while they're exposed.

ATM the glass is no longer borked or even looking 3/4 empty, maybe a tad over 1/2 full? :blink:

to this:

32 Data lines left to unwrap and clip, but I'm gonna miss the luscious loopiness of the FUBAR version. :mellow:

Address(Yellow) and Control (Blue) lines will wind up looking much like the straight across the board loop of the Data (Orange) lines that have yet to be unwapped for correction when wrapped to the proper end of the 030 PDS. Decided I can strain relief the bundles and strip in place so I won't have to start over with a new PCB. I'll work around my adhesive contaminant concerns with liberal application of larger drill bits or adding one of the small prototyping cards on hand into the mix as a daughtercard. Leaning toward the latter. Bit of good news though, the jumpered address line length is much reduced so shortening everything up will still keep the traces "meandered" and easily reworked. I'm almost tempted to go ahead and solder the wraps columns A & C on the LC side while they're exposed.

ATM the glass is no longer borked or even looking 3/4 empty, maybe a tad over 1/2 full? :blink:

Last edited by a moderator:

Sweet wrap tool! I looked at those a while back, but they were too pricey for me at the time. The flip side of that coin is a heat wire stripper that conserves integrity of the wire. Manual, bladed strippers aren't nearly as good. That SE prototyping board looks fabulous, but source a RA Wrap Connector for your slot connection. You'll be using an SE/30 type SE chassis with the adapter board installed vertically for testing one way or the other. With drive cages removed the pins can point inward. If they're outboard like my adapter, you'll need to do it in a chassis free bench setup, which is what I already have set up.

Your confidence in this is heartening, I'm still thinking along the lines of my very first statement in the IP: Dunno where this one will lead, but gotta give it a shot. :approve:

Your confidence in this is heartening, I'm still thinking along the lines of my very first statement in the IP: Dunno where this one will lead, but gotta give it a shot. :approve:

Last edited by a moderator:

Yeah, I picked it up for $20 so can't complain! I considered electric ones, but really this is a one time project. I will be doing the testing without the guys inside the machine. I want to examine what kind of options there might be fore a breakout of some kind. I like the 96 pin connectors are like 20% the price of the 120 pin connectors.Sweet wrap tool! I looked at those a while back, but they were too pricey for me at the time. The flip side of that coin is a heat wire stripper that conserves integrity of the wire. Manual, bladed strippers aren't nearly as good. That SE prorotyping board looks fabulous, but source a RA Wrap Connector for your slot connection. You'll be using an SE/30 type SE chassis with the adapter board installed vertically for testing one way or the other. With drive cages removed the pins can point inward. If they're outboard like my adapter, you'll need to do it in a chassis free bench setup, which is what I already have set up.

Just be careful about the 96 pin connectors for wire wrap. LOTS of them have only the 64 pins in columns A & C implemented. I got some of the crappy ones before I learned that 96 pin connector doesn't necessarily translate into 96 connections. 64 seems far more common than 96 in available EuroDIN for wire wrap.

Anybody know what application two of three row DIN connectors are used in today, aerospace?

Anybody know what application two of three row DIN connectors are used in today, aerospace?

Last edited by a moderator:

I saw tons of those for as low as 99 cents each, but they are useless to me. I am unaware of their applications. I'd be curious to know.

030 PDS connectors are expensive, which is OK as most SE/30 fanatics are willing to spend a little money where the SE/Plus/Classic lovers are more frugal and willing to live with settling for AppleTalk/PhoneNet. If the NIC will work in the SE, there's no reason I can think of offhand why Plus and Classic adaptations wouldn't work.

Yeah the expense for producing the PCB, parts, connectors, and assembly puts the cost fairly high. Still much cheaper than any alternative (way less than half). I was originally thinking, this would be a cheap board to build, wrong! I better stop thinking of all the possibilities because I want to build for every machine then, ha! Next think you know I’ll try to use the LC PDS NIC in Apple II machine. :lol:

Similar threads

- Replies

- 42

- Views

- 12K

- Replies

- 4

- Views

- 1K

- Replies

- 49

- Views

- 12K