You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dead Mac Plus?

- Thread starter HAL2001

- Start date

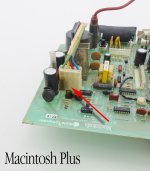

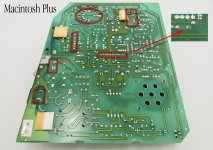

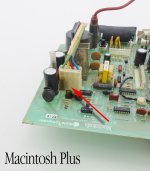

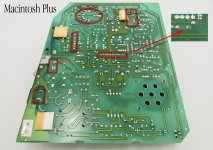

Could be as simple as bad solder joints at connectors, logic board and analog/video. A very, very common issue with the Plus and older models. Or component failure. I never fire one up without checking solder joints first since they can melt connectors, etc if bad. Plus they are very quick/easy to fix since only the bucket and shields have to come off. If those end up being fine, dig deeper. Oh, and never assume they "look fine". They cracks can be tony, reflow of solder a must. Here are some pics I made a while ago to help people.

Yes and no.

The logic board only has through-hole axial electrolytics and uses few, if any SMD components, so there's virtually no chance of cap related damage occurring. In other words, the logic board is virtually indestructible.

The analog board, on the other hand, is chock full of caps, many of which have begun to leak, making this a very weak point. Exacerbating this problem is the fact that it is prone to overheating (causing all sorts of heat-related damage), and was full of problems even when these machines were still relatively new.

Therefore, recapping the analog board (and examining/replacing any other components that may have suffered heat-related damage) is a must if you want the Plus to work reliably.

I hope this clears things up a bit

c

The logic board only has through-hole axial electrolytics and uses few, if any SMD components, so there's virtually no chance of cap related damage occurring. In other words, the logic board is virtually indestructible.

The analog board, on the other hand, is chock full of caps, many of which have begun to leak, making this a very weak point. Exacerbating this problem is the fact that it is prone to overheating (causing all sorts of heat-related damage), and was full of problems even when these machines were still relatively new.

Therefore, recapping the analog board (and examining/replacing any other components that may have suffered heat-related damage) is a must if you want the Plus to work reliably.

I hope this clears things up a bit

c

HAL2001, I have yet to meet a Plus that needed an analog board re-cap but I am sure ones exist. With the caps used they typically will dry rot out making failure hard to detect. I have never seen one myself or an example of one with leaking caps like is really common on the Classics. Caps evolved a lot over the years, sometimes for the worse.

i have not met a PLUS 128K 512k Analog board that has not NEEDED caps... Those dam things are leaking and you might not even be able to tell as they are dribbling at the base.

With the se... i have worked on a few that have not been leaking.

just like APPLE II SMPS power supplies... same way... i have not met one yet that was not at least dribbling at the base of the output stage caps of the SMPS.

With the se... i have worked on a few that have not been leaking.

just like APPLE II SMPS power supplies... same way... i have not met one yet that was not at least dribbling at the base of the output stage caps of the SMPS.

nobody can say exactly what the problem is at this stage... because it could even be burnt up flyback... or rectifier...

but after you change all the caps... and inspect the virt deflection connection for cookedness. and you can clearly see fried solder joints on the

back of the ab as they have a black ring and have been cooking and are carbon tracked up from the thermal expansion/contraction movement... that is why they need to be vacuum desoldered... then

flux + wick cleaned then re-soldered and not just " touched up "

could still be the rectifier and flyback... considering your problem. but maybe there is some life still left in those... hard to say... you can always

adjust the 5v pot , its the one in the middle of the AB, if that if its trimmed up too high .. you will get a process where the computer comes on and then shuts off, that pot does require adjustment usually after a re-cap.

but after you change all the caps... and inspect the virt deflection connection for cookedness. and you can clearly see fried solder joints on the

back of the ab as they have a black ring and have been cooking and are carbon tracked up from the thermal expansion/contraction movement... that is why they need to be vacuum desoldered... then

flux + wick cleaned then re-soldered and not just " touched up "

could still be the rectifier and flyback... considering your problem. but maybe there is some life still left in those... hard to say... you can always

adjust the 5v pot , its the one in the middle of the AB, if that if its trimmed up too high .. you will get a process where the computer comes on and then shuts off, that pot does require adjustment usually after a re-cap.

Never reflow the solder. They will just begin to crack and break after a few months time. The best thing to do is to desolder the jacks, clean then up, and put fresh solder and flux to them. It will hold much better and last for a much longer time.They cracks can be tony, reflow of solder a must. Here are some pics I made a while ago to help people.

Well I will do what has been proven to work by thousands of people. Never an issue and its fast.Never reflow the solder. They will just begin to crack and break after a few months time. The best thing to do is to desolder the jacks, clean then up, and put fresh solder and flux to them. It will hold much better and last for a much longer time.

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 5

- Views

- 515