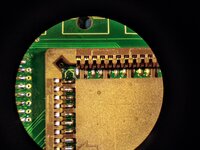

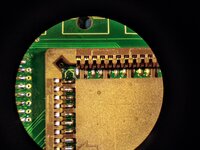

So, build update. Here's the current state of the board:

Pretty close to done. Things left on the to-do list:

I also bought the video ROM socket, CPU socket, PLCC sockets, SCSI, floppy, system ROM, and RAM sockets from Phoenix and they are all fine. The PGA CPU socket had a few pins that were mildly oxidized and took a little extra flux and heat to wet, but that's understandable since these are NOS parts. But the HWS2078 20-pin DIP sockets I would recommend staying far away from.

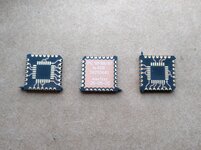

Speaking of sockets, this was my first time installing PLCC sockets. Based on what I'd seen people on YouTube do, either cutting out the bottom of the socket or using solder paste, I was a little worried about installing these, but it didn't end up being bad at all. A fine tipped iron, flux, and patience, and I found it pretty easy to get into a groove of soldering the pins by hand. I'm happy with how they came out.

Pretty close to done. Things left on the to-do list:

- Waiting for the PLCC to QFP carrier boards from OSH Park for the ADB PIC16

- Solder pins on the Bourns Again filters and install those

- Populate the RTC and surrounding components

- Install the PDS slot

- Oh yeah, NMI and reset switches, need those too; going to try 3D printing the little supports for them

- Waiting for Digi-Key to deliver 20-pin DIP sockets for the PALs

I also bought the video ROM socket, CPU socket, PLCC sockets, SCSI, floppy, system ROM, and RAM sockets from Phoenix and they are all fine. The PGA CPU socket had a few pins that were mildly oxidized and took a little extra flux and heat to wet, but that's understandable since these are NOS parts. But the HWS2078 20-pin DIP sockets I would recommend staying far away from.

Speaking of sockets, this was my first time installing PLCC sockets. Based on what I'd seen people on YouTube do, either cutting out the bottom of the socket or using solder paste, I was a little worried about installing these, but it didn't end up being bad at all. A fine tipped iron, flux, and patience, and I found it pretty easy to get into a groove of soldering the pins by hand. I'm happy with how they came out.