Wanted to share some experiments that I did recently with custom battery packs. Quick disclaimer: I know thermal fuses are missing in these photos, and I promise none of these are in active use / being charged until I add them. They were long delayed in shipping, and I had so many variables to test out that I got started without them for now while doing temporary testing.

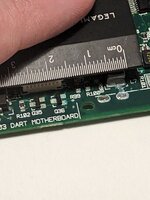

In all three, I 3d printed a new battery enclosure, and fashioned contacts by snipping 0.01" brass plate into strips. I superglued them temporarily, and then reinforced them with QuikSteel epoxy. I used a normal battery pack to ensure my contacts were properly aligned. After this process is over, it looks more or less like this:

The above is my first attempt, I do not have a spot welder or the time to build from scratch, so I wanted to see how far I'd get with an off-the-shelf 5S nimh pack. It's only 2000mAh, but I have replaced my spinny drive with a zuluscsi and was hopeful that it might be

somewhat usable. It does boot and run happily on this pack, but it begins complaining about low voltage very quickly, a mere 15 or 20 minutes in. It lasts a fair while after that, but the battery meter drops a LOT depending on activity, the floppy drive in particular makes it nose-dive. I have a suspicion that a single set of cells in series is struggling to maintain voltage at high amperage.

My next attempt was to build one using a 5-cell AA battery holder, thinking that maybe I could do better with 2800mAh cells. This actually ended up faring even worse, and would just power down when using the floppy drive. The battery holder I bought also had pretty crappy wiring, which further reinforced my lack-of-current theory. A battery holder with better wires and contacts might fare better, but it was a bit silly and would still be significantly lower capacity than a stock battery.

I did some research and found out that you can buy NIMH packs with 4/3 AF cells (I went with

these ones). These are approximately the same size as 18650 Lipo cells, and carry a whopping 4,500 mah! These packs also have much beefier wiring, so I assumed they would be able to maintain their voltage better under load, and so far in practice this has paid off. They *just* fit in my modified battery pack, and are easy enough to solder up to custom contacts. I did realize that the little half circle cutout is actually necessary

(didn't see it when I peeked in), so I had to cut a chunk out to do my testing.

I haven't done a proper full drain/runtime test, but the battery meter remains rock-solid when accessing the floppy and doing other high energy tasks, which I take to mean a higher current capacity than a AA cell pack, and the total energy capacity is a good amount above the stock battery now as well. And I didn't need to buy a spot welder!

Just wanted to share and maybe save someone else some trouble. I'll report back after a bit (and after I finalize my thermal fuse placement etc) and we'll see what kind of battery life I get. Happy to answer questions, my

modified battery pack file is on thingiverse, but I have NOT had time to add the half circle cutout back, so only print it if you don't mind just cutting an ugly hole in it with some diagonal cutters later.