pax

Well-known member

Thanks for sharing your thinking on Turbo040 support @ZaneKaminski. I'm happy to contribute to testing and QA using my SE/30. I'm in New York.

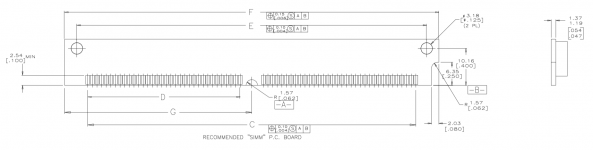

1.2mm thickness. Technically SIMMs are supposed to be 1.27mm (0.05 inches exactly) thick but 1.2mm works well enough. The usual thickness of 1.6mm is certainly too thick, I think.Are you ordering full thickness PCBs? I'd assume so, but thought it better to ask than not.

There's some tolerance so I think it'll work okay. One danger with tinning the contacts is that gold doesn't corrode and makes better electrical contact than solder and other metals. For example, it takes some force to get an accurate resistance measurement using nickel-plated multimeter probes, but almost no force is required when using gold-plated probes. So I think we're best off with just the gold pads.I've kicked around the notion of tinning the contacts on the thinner PCBs. Might doing that on one or both sides make up that 7 mil differential? Leaving off the solder mask for the contacts might just do it?

There's one bug I'm aware of which I have yet to squash in my driver: System 6-7.1 work but System 7.5 crashes on boot.

Hmm yes, I guess they are very rarely gold-plated. Either way, I don't think the layer of flux would be good for connectivity. We will look into what can be done about this, but as far as we can tell, good contact is being made.I agree completely when it comes to edge card connections, but I've rarely if ever seen 30-pin SIMMs in gold. OEM Apple ROM SIMMs are not gold plated. Dunno, maybe worth thinking about a bit? Gold's electroplated correct?

No, this is a separate issue, and yeah, the patch will be required for System 7.5 unless someone can tell me what the specific issue, and then maybe I can patch a fix into the IIsi base ROM.Speaking of System 7.5 and later, what about the patch to the System file required to get ROM-inator to work with those versions? Will the same patch be required with your ROM? Or is that the bug you're working to resolve?

Cool beans, just thought I should stick my nose in about it in case it might be helpful. Still curious about any difference there might be in thickness between gold plated vs whatever the silver stuff might be?Hmm yes, I guess they are very rarely gold-plated. Either way, I don't think the layer of flux would be good for connectivity. We will look into what can be done about this, but as far as we can tell, good contact is being made.

It's often the case that ENIG gold-plated finish is thinner than leaded/lead-free HASL finish. ENIG is electroplated (as you said), but HASL basically means that the pads are tinned and the excess solder scraped off. Inferior HASL jobs often leave the pads a bit lumpy, with not all of the solder scraped off. Thus the board thickness can be somewhat greater, but it's irregular and can create coplanarity issues when reflow soldering SMD parts. Thus ENIG was traditionally preferred for fine-pitch SMD stuff, though there are other contemporary options for "flat" finishes such as OSP (organic solderability preservatives). OSP is an orange-colored flat finish that's cheaper than ENIG (since OSP doesn't use gold) but only protects the pads from corrosion for a few weeks, so the boards must be assembled soon after they are made. OSP has become the preferred finish for cheap high-ish density boards such as in PC motherboards and game consoles.any difference there might be in thickness between gold plated vs whatever the silver stuff might be?

No offense taken--I think it's good for there to be a lot of discussion on the specifics of making this stuff. Forum threads (and USENET posts lol since this stuff is so old) are where I've gotten a lot of critical info.I hope nobody reading any of this comes off thinking any criticism at all was implied. I was only trying to be helpful, definitely not critical.

Well, I think it started about a year ago, when I noticed that BMoW’s ROMinator was discontinued. I designed a similar board, which I called ROMBUS, that plugged into the Mac’s ROM sockets but was equipped with 64 MB of cheap serial flash memory as well as the parallel flash toolbox ROM. This would allow a very fast 64MB read/write internal disk for the 512 and Plus. I redid the hardware for that project several times, and now I have a design which interfaces an SD card to the Mac Plus and 512.What is the incentive to build a ROM seeing that BMOW already has one?

Unfortunately I don’t have a Turbo040, so I think it will be difficult to troubleshoot this issue. As I said earlier about the Turbo040, I wanna know the hardware mechanism for patching the ROM, and then I could figure out the impact on the software and devise a workaround.no way to use the Turbo040 patched ROM for the ROM-inator II and have your own custom ROM disk too ... cannot use my FloppyEMU in HD20 Mode with the patched ROM and with my Turbo040 installed.

I’ve had no issues with the SIMM in my SE/30, but my SE/30 seems to be a later model with metal locking tabs on the SIMM socket, as opposed to the plastic tab socket in my IIci. Would you like to try the 2MB SIMM in your SE/30? We are going to send out a few to some testers tomorrow. If you’re not interested in the 2MB SIMM, the 2x8MB is in production and will be ready for testing soon, barring a mistake in the board.What I can say about my experience with the ROM-inator II MEGA in my SE/30 is that it is too thin

Thank you for the detailed reply. If you think I can contribute something useful while testing in my SE/30, then I would be happy to test. I can test in a stock SE/30, SE/30 with 3 different accelerators including the 40MHz Turbo040 (ROM rev.4.11), 50MHz 68030 DiiMO, and 50MHz socketed PowerCache. I also have a Floppy EMU which can be used in normal floppy mode or HD20 Mode, which is great because it acts like a bootable HD20 hard drive, yet with much more space (as your SD card allows). I also have Micron Xceed PDS video cards too, including a grayscale setup. I think this would give your beta ROMs a good testing. Be aware I am based in Japan though, if that matters. Feel free to PM me on the details. Thank you!Would you like to try the 2MB SIMM in your SE/30? We are going to send out a few to some testers tomorrow. If you’re not interested in the 2MB SIMM, the 2x8MB is in production and will be ready for testing soon, barring a mistake in the board.

Unfortunately I don’t yet have a Mac II ROMBUS design but I am thinking about it. Right now there’s just the Plus/512 version finished. The peak read speed on the Plus will be 2 bytes/12 cycles using a MOVE.W (A0), (A1)+ instruction. That’s 1.3 MB/sec. So it should be much faster than SCSI on the Mac IIci. Also keep in mind that SD cards can’t really go at the full speed of the IIfx bus. The maximum speed is around 3.125 MB/sec unless you use the proprietary and patent-pending 4-bit mode. The read speed of a ROM disk on the IIci as measured by Lido is around 8MB/sec, so SD cards are close in speed but not quite as fast. Also, SD cards have variable read latency, so there is a “seek time” imposed by the card of a few milliseconds or sometimes even more. This is frustrating compared to parallel/serial NOR flash, where there is a very small latency well under a microsecond. This will unfortunately eat into the read speed. Hence why the original ROMBUS had serial NOR flash, since the read latency is fixed at a few clock cycles. Unfortunately I had to scrap the original ROMBUS because the “wear leveling” algorithm needed to match the Mac’s 512-bytes-per-sector disk architecture to the 16 kilobyte erasable units of the NOR flash system was complicated and used like 256kB of RAM. So basically reads would have been very fast but writes would be complicated and every once in a while take a long time. So I switched to SD card, which has similar limitations but does all of the write leveling for you internally. It’s easier, and the disk will be larger as well.If I got that right, you'll be accessing SD on the memory bus at 16MHz, 20MHz, 25MHz and even 40MHz? 8-o