macfan2350

Member

Hi all!

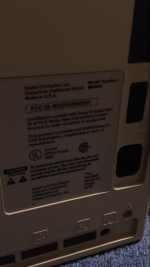

I have a Macintosh 128k, and when I go to turn it on, I get no startup bong, but I get a fine vertical line in the middle of the screen.

Any help is welcome

I have a Macintosh 128k, and when I go to turn it on, I get no startup bong, but I get a fine vertical line in the middle of the screen.

Any help is welcome