bushok

Well-known member

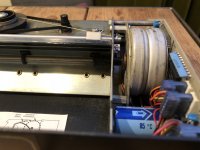

Hi, I've just brought my Apple SilenType printer back to life yesterday, hooked up on my Apple II Europlus. Amazing it still prints.

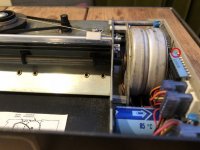

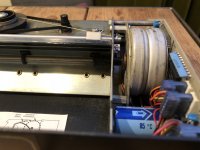

There is just one problem: it won't move the print roll. So lines are printed on top of each other. I suspect a defective electric motor on the print roll rod.

Does anybody here know what the problem could be?

There is just one problem: it won't move the print roll. So lines are printed on top of each other. I suspect a defective electric motor on the print roll rod.

Does anybody here know what the problem could be?