You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PowerBook 1400 battery - what cell type?

- Thread starter 3lectr1cPPC

- Start date

Yes, you need cells called 4/3A, 8 of them. Make sure to get the ones that do NOT have the nubs at the end, as they won’t fit in the battery case. If you have a Batteries Plus store near you, it’s easy: bring in the original cells to them. They will shrink wrap the new cells in series 2 each, and duplicate the tabs between the cells by tack welding them on in the same orientation…for free. Makes it a whole lot easier.

Here is an example of the cells:

www.batteriesplus.com

www.batteriesplus.com

Here is an example of the cells:

FDK 4/3A NiMH Flat Top Industrial Rechargeable Cell - SANHR4/3AU

SANHR4/3AU FDK 4/3A NiMH Flat Top Industrial Rechargeable Cell

I feel a bit like how other people in my life must feel when talking about recapping and fixing these macs... are you saying that they can take care of the welding for me? That would indeed be quite helpful. Could they do the whole pack in fact? I've got a 500 series battery too, already cracked open, electronics removed. Just need to get new cells on.They will shrink wrap the cells in series 2 each, and duplicate the tabs between the cells by tack welding them on in the same orientation…for free. Makes it a whole lot easier.

1400 battery as well, got the cells disconnected from all the internal electronics. No damage to the important stuff.

I’m not sure I ever documented my battery pack rebuild…I’ll have to rectify that.

So, I’m brief: the pack has the cells either connected one to the other, or connected to electronics and what I believe is a thermistor. They will duplicate the orientation of those tabs if you ask…so like if cell 5 has a tab between its positive and the negative of cell 6, they will weld a similar flat metal strip between the two corresponding new cells. They will also weld and bend into place “free” tabs (welded to one spot, then leading to nothing), so that you can manually solder the original electronic part where it should go.

I’ve got good pics of this, I’ll have to get them at home tonight. I don’t believe they will attach the electronics…that’s beyond what they do.

So, I’m brief: the pack has the cells either connected one to the other, or connected to electronics and what I believe is a thermistor. They will duplicate the orientation of those tabs if you ask…so like if cell 5 has a tab between its positive and the negative of cell 6, they will weld a similar flat metal strip between the two corresponding new cells. They will also weld and bend into place “free” tabs (welded to one spot, then leading to nothing), so that you can manually solder the original electronic part where it should go.

I’ve got good pics of this, I’ll have to get them at home tonight. I don’t believe they will attach the electronics…that’s beyond what they do.

Thanks for the explanation - if batteries+bulbs (seems to be the same place to me, the naming is confusing) can weld the cells themselves together, I think I could handle the rest. Sounds like I have a plan! Will probably do my 500 series pack first though.

And yes, any documentation that you have on the 1400 battery would be very useful! I'm making a page on MacDat with a table with all the different cell types of these batteries, will eventually add info too on rebuilding each pack.

And yes, any documentation that you have on the 1400 battery would be very useful! I'm making a page on MacDat with a table with all the different cell types of these batteries, will eventually add info too on rebuilding each pack.

Sounds good.

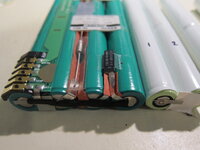

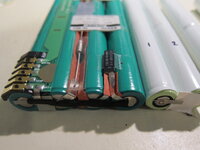

So, in case you hadn't opened it yet, here is the original pack:

You can see how the strips are tack welded and run at certain angles to meet certain things.

I then received the new cells shrink wrapped end to end, and labeled them 1-4 from one end to the other to line up where each tab went.

There was tape used to simulate the spacers, but I removed that and added the original spacers. Lastly, I clipped off the electronics at the tabs half-way through, and then soldered those to the new tabs as can be seen in the next photo. You can see the long strap at the top how in the right-upper corner, the original PCB strip is soldered after the 90 degree bend to the tab coming up from the new battery. Same with the others, but harder to see:

You can see how the strips are tack welded and run at certain angles to meet certain things.

I then received the new cells shrink wrapped end to end, and labeled them 1-4 from one end to the other to line up where each tab went.

There was tape used to simulate the spacers, but I removed that and added the original spacers. Lastly, I clipped off the electronics at the tabs half-way through, and then soldered those to the new tabs as can be seen in the next photo. You can see the long strap at the top how in the right-upper corner, the original PCB strip is soldered after the 90 degree bend to the tab coming up from the new battery. Same with the others, but harder to see:

Yeah I’ve opened mine up already. Thanks for the info, will be quite helpful.

Years later - how is the batteries going LaPorta?

Cheers

AP

Cheers

AP

Hey! Well, I’ve had a mixed bag. One is not doing well: not sure if I left it too long without charging. The other is doing great: even a few years later, I can get a solid hour plus from it, more if not heavy use. I also just this past December rebuilt one for the 1400 I restored for my daughter, and that one is working well too.

I finally rebuilt mine a few months ago, I get about 2.5 hours from it with moderate usage. This was using Tenergy 4/3A cells. Will have to see how it holds up in the long term.

Quick question; is there a specific sequence to reconnect the chip/main board?

Cheers

AP

Cheers

AP

I was going to use @cheesestraws 's approach to rebuilding my battery by using batteries that have a nub; which you don't need to weld (as I won't be able to do any welding). I was thinking of getting some suitable ones from RS or Farnell along with some other stuff in a combo order, but can't seem to find the ones Cheese Straws was talking about.I finally rebuilt mine a few months ago, I get about 2.5 hours from it with moderate usage. This was using Tenergy 4/3A cells. Will have to see how it holds up in the long term.

I don't think that was my technique, rebuilding batteries is too scary for me - @croissantking rebuilt mine, were you thinking of him?

Ditto, nubbed batteries won't fit.The nub batteries are too big end to end to close the case when you are done. Usually the place you get the batteries at will tack weld strips on for you (at least they will here).

Tenergy seems to be the only place in the US that offers name-brand 4/3A cells (the rest are all generics). On their website, you can pick between cells with tabs pre-attatched, or cells without tabs. The one annoying thing is they've about doubled in price in the past year, tariffs I'd guess...

Similar threads

- Replies

- 9

- Views

- 670

- Replies

- 13

- Views

- 1K

- Replies

- 11

- Views

- 4K