Hi all,

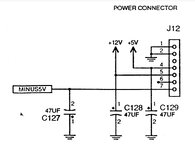

I've been trying to recap my LC475. I recapped the TDK-PSU, worked out fine. Than I did the motherboard, aaaand... while removing the second to last cap (C129) a pad came loose. Bad luck I guess. I searched the web, found many solutions but none of those seem to work in this case:

Can any of you give or point me to a possible solution? Can I run a wire to another part of the board? Anything else?

Also, can anyone tell me what this cap is needed for? I haven't tried booting it yet but if it could work with say, the loss of a functional floppy drive or something else one could do without, I could live with the damage (for now).

Thanks,

oneman

I've been trying to recap my LC475. I recapped the TDK-PSU, worked out fine. Than I did the motherboard, aaaand... while removing the second to last cap (C129) a pad came loose. Bad luck I guess. I searched the web, found many solutions but none of those seem to work in this case:

- Fix 1: use a through board hole the pad was connected to by soldering some enamelled wire to it: there's no hole, just a very small pin through the board. I scraped the pin slightly free, but it's to small and no solder will stick to it

- Fix 2: Solder to a trace in the board's surface: i freed some copper coloured trace, but no solder will stick to it & not sure this is even a real trace or even the right one.

Can any of you give or point me to a possible solution? Can I run a wire to another part of the board? Anything else?

Also, can anyone tell me what this cap is needed for? I haven't tried booting it yet but if it could work with say, the loss of a functional floppy drive or something else one could do without, I could live with the damage (for now).

Thanks,

oneman