I've been working through my first Lisa 2/10 and have the machine working well enough to want to try using the Widget drive.

I've gotten through many of the common issues. It initially was reticent about spinning up and was noisy, but after considerable cleaning and prodding it now spins up, needing a gentle push about 50% of the time to get started. The bearing is not what I'd call whisper quiet, but it's definitely quieter than I feared and seems to get quieter with use.

The brake on the head actuator was releasing on spin up quite reliably, but this has stopped happening. The head actuator moves freely and at various times has seeked successfully and read data. Currently the head does not release, but I'm somewhat confident the servo loop on the spindle motor has closed, as the index pulse period on the scope is very steady (is there a way to confirm that the loop is closed?)

Currently I am getting error 81 when starting up after a significant wait and some very brief, small movements of the head actuator. Before that I was getting error 82 nearly immediately after a bit more head activity. I also get error 85 spuriously. NeoWidEx currently reports that no drive is connected.

Prior to this, I had a period where the drive was successfully recognized. Watching the head, it would do a slow scan across the drive surface and the happily seek back and forth under control. It would usually get into the MacWorks "loading" screen, but the most common outcome was a hang there. On one or two occasions it successfully booted into MacOS System 6. I was able to open files and run programs from the Widget without trouble. I was thrilled, but sadly it was short-lived.

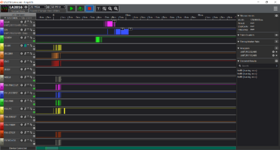

I started probing the BUSY and CMD lines and can confirm that currently BUSY is asserted while the drive is spinning up and remains asserted except perhaps for a few pulses. Consequently CMD is only asserted in a few quick pulses and then has no further activity. This seems to jive with the behavior on the Lisa end.

So I was wondering if anyone there can help me try to diagnose the drive? I have a two-channel sampling scope and logic analyzer and intermediate level expertise on how to use them. I'm just not well versed on how to narrow down the problem with a Widget. It occurs to me that these symptoms are plausibly consistent with a problem with the encoder grating, but I am reluctant to open the drive if it's not needed.

I'm also struggling with having, perhaps, not quite the correct schematics. For example, my controller board is P/N 667-0110-C (two layer controller), and I can't seem to find schematics for that anywhere. Using the schematic for 050-5023-B, most things seem similar but I can't always be sure that discrepancies are due to the schematic or a fault.

Thanks for any help and I will also post this on LisaList2.

I've gotten through many of the common issues. It initially was reticent about spinning up and was noisy, but after considerable cleaning and prodding it now spins up, needing a gentle push about 50% of the time to get started. The bearing is not what I'd call whisper quiet, but it's definitely quieter than I feared and seems to get quieter with use.

The brake on the head actuator was releasing on spin up quite reliably, but this has stopped happening. The head actuator moves freely and at various times has seeked successfully and read data. Currently the head does not release, but I'm somewhat confident the servo loop on the spindle motor has closed, as the index pulse period on the scope is very steady (is there a way to confirm that the loop is closed?)

Currently I am getting error 81 when starting up after a significant wait and some very brief, small movements of the head actuator. Before that I was getting error 82 nearly immediately after a bit more head activity. I also get error 85 spuriously. NeoWidEx currently reports that no drive is connected.

Prior to this, I had a period where the drive was successfully recognized. Watching the head, it would do a slow scan across the drive surface and the happily seek back and forth under control. It would usually get into the MacWorks "loading" screen, but the most common outcome was a hang there. On one or two occasions it successfully booted into MacOS System 6. I was able to open files and run programs from the Widget without trouble. I was thrilled, but sadly it was short-lived.

I started probing the BUSY and CMD lines and can confirm that currently BUSY is asserted while the drive is spinning up and remains asserted except perhaps for a few pulses. Consequently CMD is only asserted in a few quick pulses and then has no further activity. This seems to jive with the behavior on the Lisa end.

So I was wondering if anyone there can help me try to diagnose the drive? I have a two-channel sampling scope and logic analyzer and intermediate level expertise on how to use them. I'm just not well versed on how to narrow down the problem with a Widget. It occurs to me that these symptoms are plausibly consistent with a problem with the encoder grating, but I am reluctant to open the drive if it's not needed.

I'm also struggling with having, perhaps, not quite the correct schematics. For example, my controller board is P/N 667-0110-C (two layer controller), and I can't seem to find schematics for that anywhere. Using the schematic for 050-5023-B, most things seem similar but I can't always be sure that discrepancies are due to the schematic or a fault.

Thanks for any help and I will also post this on LisaList2.