Hello all - I am extremely new to PCB work, and I have a SE/30 that I dove into after watching enough YouTube videos to think I know something.

In any case - when removing and attempting to reinstall the axial cap on CB, I smoked this connection. I have tried to melt what solder was there to clear it, but I think I may have actually damaged the pad beyond my capabilities. I am aware of my novice-ness on board that I should have practiced elsewhere on - but I my question is - is this salvagable? I am considering getting a tiny drill bit to get the hole cleared out, but I wanted to reach out for help before I go any further...

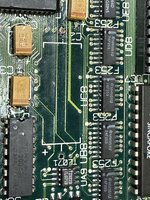

The pictures show my destruction...I know I overheated it trying to get the old soldier out...

In any case - when removing and attempting to reinstall the axial cap on CB, I smoked this connection. I have tried to melt what solder was there to clear it, but I think I may have actually damaged the pad beyond my capabilities. I am aware of my novice-ness on board that I should have practiced elsewhere on - but I my question is - is this salvagable? I am considering getting a tiny drill bit to get the hole cleared out, but I wanted to reach out for help before I go any further...

The pictures show my destruction...I know I overheated it trying to get the old soldier out...