Hi....

My Color Classic has always had a perfect screen. No bleeding of colors, no off colors, just perfect in every way.

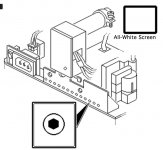

While I was running it today, I rebooted and it booted to a purple screen. Everything worked, except everything had a purple shade to it. I rebooted again and same thing happened. I shut it down, then did a cold boot and same thing happened.

My logic board has just been re cap'ed and so has my analog board. I do not have any extra boards to swap out. I did drop in my older hard drive and that was not it.

After that, I took the case off to see if I had any loose wires or anything. I found nothing visibly disconnected or not plugged in correctly. I sure hope it is not my CRT.

Any suggestions on where to start looking for trouble?

Thanks in advance

jack

My Color Classic has always had a perfect screen. No bleeding of colors, no off colors, just perfect in every way.

While I was running it today, I rebooted and it booted to a purple screen. Everything worked, except everything had a purple shade to it. I rebooted again and same thing happened. I shut it down, then did a cold boot and same thing happened.

My logic board has just been re cap'ed and so has my analog board. I do not have any extra boards to swap out. I did drop in my older hard drive and that was not it.

After that, I took the case off to see if I had any loose wires or anything. I found nothing visibly disconnected or not plugged in correctly. I sure hope it is not my CRT.

Any suggestions on where to start looking for trouble?

Thanks in advance

jack