@pbertolo I know the mechanism you're talking about. The bezel can be taken off, but be careful, there are two brittle clips on either end. It may just need to be cleaned. Probably dirt and grime on the hinges for the door mechanism. I seem to recall I fixed mine with a very small amount of 3-in-1 oil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

540MB MO in Fujitsu 640MB DynaMO?

- Thread starter trag

- Start date

Thanks for the tip! I will try and see what I can do…@pbertolo I know the mechanism you're talking about. The bezel can be taken off, but be careful, there are two brittle clips on either end. It may just need to be cleaned. Probably dirt and grime on the hinges for the door mechanism. I seem to recall I fixed mine with a very small amount of 3-in-1 oil.

I just gave it a quick look, the issue lays in the mechanics of the eject mechanism.

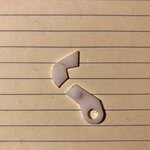

As you can see from the picture, there’s a rotating cam, which acts on a pin, translating rotational movement into linear one.

Apparently, nothing looks damaged, just kind of snapped out of position (even though there seems to be a tiny gear train that I still have to inspect, but the cam always rotates back to initial position, so it should be OK).

As is now, as the cam reaches rearmost position (270 deg), the pin just slips under the cam and the sledge is abruptly pulled back to closed position by the action of the springs.

Seems to me that by fiddling with the mechanical eject and pushing the eject button at the same time, the whole mechanism went out of synchronization.

I’d need to see a working drive for figuring out a fix…

As you can see from the picture, there’s a rotating cam, which acts on a pin, translating rotational movement into linear one.

Apparently, nothing looks damaged, just kind of snapped out of position (even though there seems to be a tiny gear train that I still have to inspect, but the cam always rotates back to initial position, so it should be OK).

As is now, as the cam reaches rearmost position (270 deg), the pin just slips under the cam and the sledge is abruptly pulled back to closed position by the action of the springs.

Seems to me that by fiddling with the mechanical eject and pushing the eject button at the same time, the whole mechanism went out of synchronization.

I’d need to see a working drive for figuring out a fix…

I had the exact same problem as you, I recently got an Fujitsu FN640 external MO drive, it also couldn't insert a MO disc. So how's your progress? Would it be feasible to make a similar part from sheet metal? I haven't disassembled my drive yet as I'm new to machining and would like to disassemble my MO drive and fix it if it's not too difficult.Sad, short story. The loading mechanism is not OK, because there’s a broken piece.

Fatigue. Such a lousy design I could hardly believe.

It’s completely nonsensical, but as the part is almost flat, I will see if it’s possible to make a better one out of some soft metal.

I managed to fix this piece by reinforcing it with Alu sheet (0.2 mm) and epoxy resin for keeping everything together.I had the exact same problem as you, I recently got an Fujitsu FN640 external MO drive, it also couldn't insert a MO disc. So how's your progress? Would it be feasible to make a similar part from sheet metal? I haven't disassembled my drive yet as I'm new to machining and would like to disassemble my MO drive and fix it if it's not too difficult.

The metal sheet is now bearing all the mechanical stress, the originals plastic pieces fulfil the function.

Couldn’t find a better picture, sorry.

Thanks for your reply. This shape looks difficult to machine. I originally considered using a thin iron sheet to achieve this shape by grinding, but now it does not seem to be easy. Your method is very clever and I plan to try it when I have time.I managed to fix this piece by reinforcing it with Alu sheet (0.2 mm) and epoxy resin for keeping everything together.

The metal sheet is now bearing all the mechanical stress, the originals plastic pieces fulfil the function.

Couldn’t find a better picture, sorry.

Thanks. I also considered something more refined, but eventually I concluded it was not worth the effort. This solution may not look so elegant, but it’s effective. The Al sheet can be easily trimmed with basic tools, so indeed it just took me one hour of work, plus the setting time for the epoxy.Thanks for your reply. This shape looks difficult to machine. I originally considered using a thin iron sheet to achieve this shape by grinding, but now it does not seem to be easy. Your method is very clever and I plan to try it when I have time.

Attachments

Cool! Very good information.

Was a copy of this CD image backed up somewhere?I posted an image of the CDROM that came with the external SCSI 640MB DynaMO drive here: https://www.prismnet.com/~trag/Mac_Drivers/

The disk is imaged using Apple Disk Copy 6.3.3. I think Anarchie must have added the .bin. So it looks like you might need software to de-binhex it and then Disk Copy to mount the image. When it's all uncompressed, it's only about 50MB.

All of my content formerly at prismnet.com/~trag is now at sphinxgroup.org. Do not add the ~trag at the end. tigertech handles web space a little differently from how prismnet did.Was a copy of this CD image backed up somewhere?

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 11

- Views

- 782