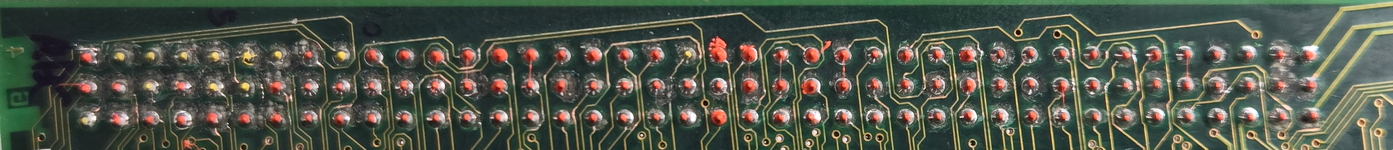

At VCFMW, @Complexhvac came by my booth with a DiimoCache that had been terribly, terribly abused, a garage sale find. It looked to me like a write off, good for parts only. It was covered in blue painter's tape where it'd been attempted to be bodged by the prior owner. However, I couldn't resist giving it a go ... apparently I have a predilection for basket cases. Let's start peeling the onion and figure the damages.

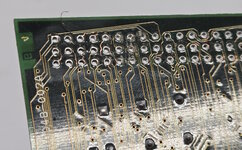

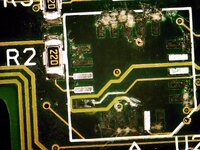

Lot of magnet wire.... PDS connector has clearly been removed, poorly, and CPU swapped.

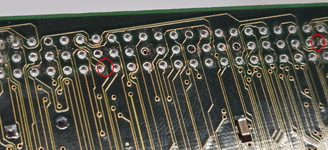

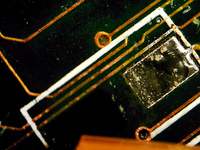

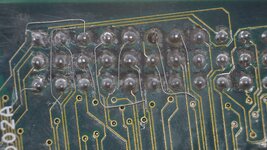

Yes, that is a whole trace hanging off the board. ☠

This is what I came up with.

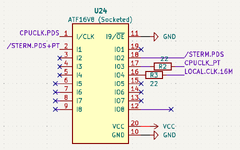

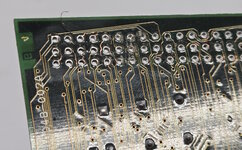

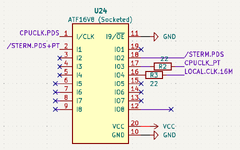

The U24 GAL crater is an ugly mess but it only actually needs a few connections. Thanks to bolle's efforts the schematic for this board is known, and I'm quite familiar with it since I made a socketed clone of my own. U24 just conditions sterm and the clocks, little else. With so many NC pins that is likely why those pads came off when it was being desoldered. A total of 4 bodges are needed. Done. I reprogrammed U24 with the stock code just to be safe, this also serves as a way to validate the GAL is (probably) fine.

Incidentally, Bolle informed me the motley collection of GALs is normal; apparently micromac was scraping the bottom of the barrel with these cards and using whatever they could lay hands on. The PCB was dated 3rd week of 2000 so it's very late production indeed for a machine that ceased being relevant long before that.

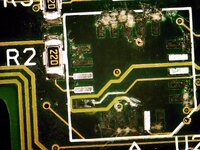

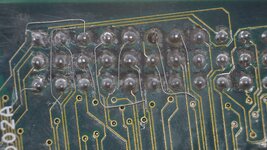

Next comes the trace repairs. These are accomplished with a single strand from a 30 (?) AWG SCSI cable, around 40 gauge wire.

Now the card attempts to run - I can see the CPU coming out of reset and "twitching" on my blinkenPDS card. Closer to life, at least; it was stone dead before. I inspect the board further and find no obvious further trace damage. Further inspection finds the weak solder mask near one of the tantulums has given way and I caused a bridge - oops. This is something to watch out for when placing tantulums in place of electrolytics during recapping of any vintage boards, either use small replacement caps, or take care that the contact surfaces of the cap are not resting on/above traces.

Now the card walks the bus! Yes! A *lot* has to be working to get this far, but it still can't boot, either the Mac ROM or my bare metal test program. So the CPU is either reading wrong addresses in ROM (address lines) or getting bad data (data lines). Well, let's have a look at that PDS connector, there is a chance a trace passes in proximity to the damaged areas during desoldering. There could also be traces using a through-hole as a via up top.... weird, but you never know.

An aside on the board design: The trace routing on this board is neurotic, it doesn't have a coherent logic to the routing like you see on other period designs. Look at Daystar cards for an example: they were laid out with care and a certain logic to the routing. Per a friend of mine with period industry experience this is because the DiimoCache SE30 was autorouted with assistance from a human, leading to these strange "choices". This card is essentially the DiimoCache 030 for IIci jammed onto the same board as the DiimoCache SE30 adapter, late (1996), so it makes sense that it perhaps didn't receive as much care as it might have if designed when the SE30 was in its heyday.

An interesting tidbit is the card actually has 128KB of cache onboard but only uses half of it, the original card used 4 bit wide SRAMs and the SE30 design uses 8 bit wide chips due to availability. This is one of the few changes to the basic design with the SE30 version. Sadly, if Micromac's engineers had run a single additional address line to each SRAM they'd have been able to use the full 128K; I've performed this modification to my socketed variant. MicroMac also added a flipflop to halve the FPU's clock speed to 25mhz - I suspect this is due to the difficulty of sourcing PGA parts rated for 50mhz operation.

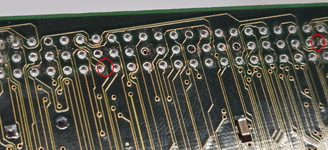

Destroyed traces near the desoldered connector is exactly what happened. Two bodges later - D8, and IPL2 - it boots! And the cache even works, great!

Now the next steps are to clean up, reinstall the PDS connector, and bodge that to life. So let's get to it. The card stops booting after the connector is reinstalled.... because loose trace ends have gotten soldered to other pins. Oops. I have to go clean all those off while consulting pictures of an undamaged card. OK, great: works, again. Let's tone out and see what pins are bad up top.

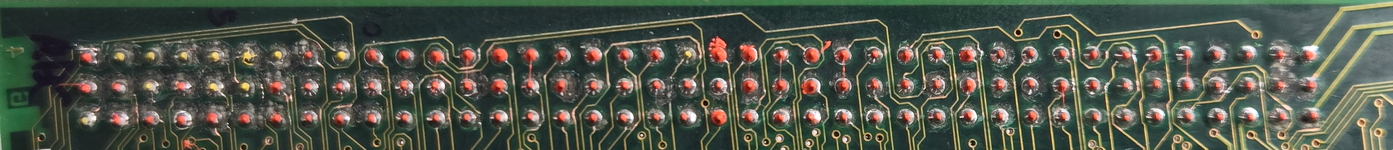

Yikes. Orange is good, yellow bad. (I grabbed the first two paint pens I had, sue me)

This is where things go awry. There's been no electrical changes since getting the PDS connector reinstalled and the bad hanging traces removed. Just some inspection and toning. It should still work, but it crashes when the cache is enabled. Ughhhhh. OK, well, I clearly messed something up, let's remove things one at a time and eliminate variables.

In order of desperation, this is what I did, all without a change in behavior. Instant lock when cache turns on.

Now I have to undo every (unneccisary) change made during troubleshooting. Reinstall the FPU, original cache, PDS connector, oscillator, caps. Yay. Perform all this and the cache still works. What a faff that was.

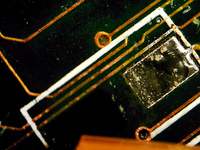

At least getting a new microscope was long overdue. The mount isn't perfect and the accessories are junk, but the camera and scope lens are fantastic. My review of the microscope is here. Time to make good use of it....

Turns out working under a microscope is fun! My prior pluggable scope really wasn't good enough for this, nor did it have a long enough working distance (distance between lens and item) to allow me to manuver my hands and soldering iron around. I didn't realize I could make these fine movements, this makes it almost easy. I enjoyed this.

The card is now fully repaired and functionally tests OK. Finally. Time to slather all bodges in conformal coating, especially that poor U24 GAL that's held on by 5 pads only, and the caps.

It will never be a looker but it works. I don't know that I'd ever really trust it - that GAL 'death' is concerning - but I was looking for something to tinker with and certainly got that. I still don't have a theory as to what happened with that GAL, maybe some kind of shock damage. There's certainly evidence enough of that.

I still have no idea what the thought process behind the previous owner's work was but I can almost admire the sheer bloodymindedness that went into it. Though I dare say I wasn't far off that myself by the time it was done....

Lot of magnet wire.... PDS connector has clearly been removed, poorly, and CPU swapped.

Yes, that is a whole trace hanging off the board. ☠

This is what I came up with.

- The board is covered in gouges, cutting tracks.

- 4/5 bulk capacitors had a pad ripped off.

- The U24 GAL was attempted to be desoldered, leaving what I can only describe as a crater

- The CPU has been replaced with a MC68EC030, which can't work with Mac OS due to lack of MMU

- The PDS pass-through connector has been messily desoldered, damaging traces

- The GALs are a motley lot; preprogrammed lattice parts, apple branded parts, and off the shelf GALs. Has someone been swapping?

The U24 GAL crater is an ugly mess but it only actually needs a few connections. Thanks to bolle's efforts the schematic for this board is known, and I'm quite familiar with it since I made a socketed clone of my own. U24 just conditions sterm and the clocks, little else. With so many NC pins that is likely why those pads came off when it was being desoldered. A total of 4 bodges are needed. Done. I reprogrammed U24 with the stock code just to be safe, this also serves as a way to validate the GAL is (probably) fine.

Incidentally, Bolle informed me the motley collection of GALs is normal; apparently micromac was scraping the bottom of the barrel with these cards and using whatever they could lay hands on. The PCB was dated 3rd week of 2000 so it's very late production indeed for a machine that ceased being relevant long before that.

Next comes the trace repairs. These are accomplished with a single strand from a 30 (?) AWG SCSI cable, around 40 gauge wire.

Now the card attempts to run - I can see the CPU coming out of reset and "twitching" on my blinkenPDS card. Closer to life, at least; it was stone dead before. I inspect the board further and find no obvious further trace damage. Further inspection finds the weak solder mask near one of the tantulums has given way and I caused a bridge - oops. This is something to watch out for when placing tantulums in place of electrolytics during recapping of any vintage boards, either use small replacement caps, or take care that the contact surfaces of the cap are not resting on/above traces.

Now the card walks the bus! Yes! A *lot* has to be working to get this far, but it still can't boot, either the Mac ROM or my bare metal test program. So the CPU is either reading wrong addresses in ROM (address lines) or getting bad data (data lines). Well, let's have a look at that PDS connector, there is a chance a trace passes in proximity to the damaged areas during desoldering. There could also be traces using a through-hole as a via up top.... weird, but you never know.

An aside on the board design: The trace routing on this board is neurotic, it doesn't have a coherent logic to the routing like you see on other period designs. Look at Daystar cards for an example: they were laid out with care and a certain logic to the routing. Per a friend of mine with period industry experience this is because the DiimoCache SE30 was autorouted with assistance from a human, leading to these strange "choices". This card is essentially the DiimoCache 030 for IIci jammed onto the same board as the DiimoCache SE30 adapter, late (1996), so it makes sense that it perhaps didn't receive as much care as it might have if designed when the SE30 was in its heyday.

An interesting tidbit is the card actually has 128KB of cache onboard but only uses half of it, the original card used 4 bit wide SRAMs and the SE30 design uses 8 bit wide chips due to availability. This is one of the few changes to the basic design with the SE30 version. Sadly, if Micromac's engineers had run a single additional address line to each SRAM they'd have been able to use the full 128K; I've performed this modification to my socketed variant. MicroMac also added a flipflop to halve the FPU's clock speed to 25mhz - I suspect this is due to the difficulty of sourcing PGA parts rated for 50mhz operation.

Destroyed traces near the desoldered connector is exactly what happened. Two bodges later - D8, and IPL2 - it boots! And the cache even works, great!

Now the next steps are to clean up, reinstall the PDS connector, and bodge that to life. So let's get to it. The card stops booting after the connector is reinstalled.... because loose trace ends have gotten soldered to other pins. Oops. I have to go clean all those off while consulting pictures of an undamaged card. OK, great: works, again. Let's tone out and see what pins are bad up top.

Yikes. Orange is good, yellow bad. (I grabbed the first two paint pens I had, sue me)

This is where things go awry. There's been no electrical changes since getting the PDS connector reinstalled and the bad hanging traces removed. Just some inspection and toning. It should still work, but it crashes when the cache is enabled. Ughhhhh. OK, well, I clearly messed something up, let's remove things one at a time and eliminate variables.

In order of desperation, this is what I did, all without a change in behavior. Instant lock when cache turns on.

- Re-do all trace bodges

- Remove all caps.

- Remove the top connector.

- Test the oscillator, replace it anyways

- Tone-out portions of the internal address and data busses

- Replace all cache data and tag SRAMs.

- Remove the FPU.

- Ultrasonic clean the board

- Remove and re-verify U24.

- Despair

- Buy a new microscope and re-inspect the board and all bodges

- Scan and tone around randomly

Now I have to undo every (unneccisary) change made during troubleshooting. Reinstall the FPU, original cache, PDS connector, oscillator, caps. Yay. Perform all this and the cache still works. What a faff that was.

At least getting a new microscope was long overdue. The mount isn't perfect and the accessories are junk, but the camera and scope lens are fantastic. My review of the microscope is here. Time to make good use of it....

Turns out working under a microscope is fun! My prior pluggable scope really wasn't good enough for this, nor did it have a long enough working distance (distance between lens and item) to allow me to manuver my hands and soldering iron around. I didn't realize I could make these fine movements, this makes it almost easy. I enjoyed this.

The card is now fully repaired and functionally tests OK. Finally. Time to slather all bodges in conformal coating, especially that poor U24 GAL that's held on by 5 pads only, and the caps.

It will never be a looker but it works. I don't know that I'd ever really trust it - that GAL 'death' is concerning - but I was looking for something to tinker with and certainly got that. I still don't have a theory as to what happened with that GAL, maybe some kind of shock damage. There's certainly evidence enough of that.

I still have no idea what the thought process behind the previous owner's work was but I can almost admire the sheer bloodymindedness that went into it. Though I dare say I wasn't far off that myself by the time it was done....