ClassicGuyPhilly

Well-known member

Hi all,

I've reconsidered doing the recap on the IIfx myself. I'd still like to learn to solder, and since I want an LC and IIci in my eventual collection, makes way more sense to recap those models after much practice and leave the IIfx to a professional.

After a few inquiries, I've located an area TV Repair Shop and talked with them. While the person I spoke with said a tech would need to check the board out in person, they have experience with such vintage computer work.

So, my scope of work starts with:

Logicboard

Battery Holder replacement x2

Tantalum capacitor replacement - C24 and C9

In for a penny, in for a pound, so I think makes sense to also hit any other soldering work that may be beneficial and proactive to preserve the machine.

Power Supply - I've found capacitor replacement kits (link below) for the GE and Delta Mac II power supplies, but none for a Sony model. I haven't taken apart my power supply yet, but if there are electrolytic capacitors in there, or anything else potentially suspect, IMO should replace. I also read on an Apple II thread that sometimes old capacitors may work in power supplies but may not consistently hold the proper voltage.

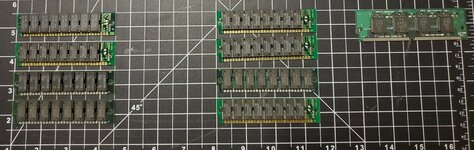

Video Card - I've also found a capacitor replacement kit for a Mac II video card, but not sure if that's for my Toby. But if there are components on the video card that should be replaced, fair game too.

https://console5.com/store/computer-cap-kits/mac-68k-cap-kits/mac-ii-series-cap-kits.html

Am I missing anything else?

Trying to do as much research as I can, but I'm still in way over my head with the restoration work.

I will probably wait to actually perform the work until later (need a monitor, KB, Mouse first), but I think getting a quote for the soldering SOW soon is a good move.

Thanks!

I've reconsidered doing the recap on the IIfx myself. I'd still like to learn to solder, and since I want an LC and IIci in my eventual collection, makes way more sense to recap those models after much practice and leave the IIfx to a professional.

After a few inquiries, I've located an area TV Repair Shop and talked with them. While the person I spoke with said a tech would need to check the board out in person, they have experience with such vintage computer work.

So, my scope of work starts with:

Logicboard

Battery Holder replacement x2

Tantalum capacitor replacement - C24 and C9

In for a penny, in for a pound, so I think makes sense to also hit any other soldering work that may be beneficial and proactive to preserve the machine.

Power Supply - I've found capacitor replacement kits (link below) for the GE and Delta Mac II power supplies, but none for a Sony model. I haven't taken apart my power supply yet, but if there are electrolytic capacitors in there, or anything else potentially suspect, IMO should replace. I also read on an Apple II thread that sometimes old capacitors may work in power supplies but may not consistently hold the proper voltage.

Video Card - I've also found a capacitor replacement kit for a Mac II video card, but not sure if that's for my Toby. But if there are components on the video card that should be replaced, fair game too.

https://console5.com/store/computer-cap-kits/mac-68k-cap-kits/mac-ii-series-cap-kits.html

Am I missing anything else?

Trying to do as much research as I can, but I'm still in way over my head with the restoration work.

I will probably wait to actually perform the work until later (need a monitor, KB, Mouse first), but I think getting a quote for the soldering SOW soon is a good move.

Thanks!