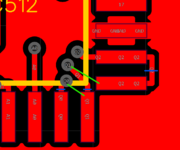

Here's a reworked cartridge. The PLCC socket was a PITA to remove but did eventually let go. The main fallout was that a couple areas lost a bit of solder mask.

This is what I did to get the socket off:

1) Sopped up as much solder with wick as possible.

2) Placed a hobby knife on the side with U2, using that as a fulcrum.

3) Heated the pins on that side until there was enough space to fit a small flathead screwdriver where the knife was.

4) Worked from left to right heating up pins to create a larger and larger wedge and eventually removed the connector.

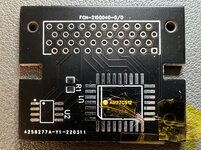

Rework of the board itself was identical to the previous post. This one tested fine after rework too.

View attachment 39785