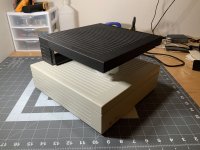

@PotatoFi It is looking really good! Very impressive, if you think that is a long print, imagine trying to do an entire SE/30... I think if we can figure out what kind of standoffs are needed and can create a CAD for the back panel I can contact my guy and see what can be done. I'm not really sure wood is practical for this application though it would sure look slick.

I know, right?! I think you had a prototype of an SE/30 case FDM printed, right? By the way, I saw your clear SE/30 case in-person this week. It's absolutely gorgeous! By the way, let me know if you'd like your hard drive back with a printed case.

As for the the wood... I only wanted to point out the absurdity of 3D printing this thing. :lol: I personally want plastic, and only plastic.

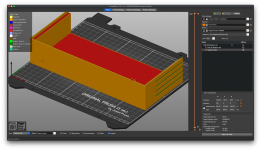

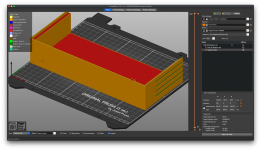

For those that don't know,

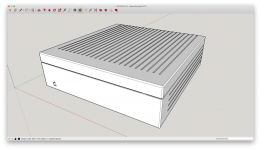

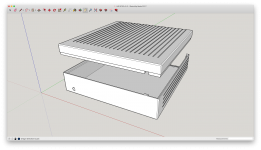

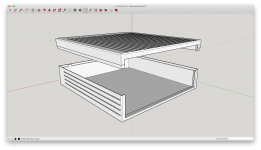

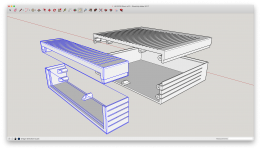

@maceffects basically sponsored this project. The 20SC that you see above is his, lent to me to make the model. I'll be providing the completed model for MacEffects to modify/use for whatever, although I did it in SketchUp which is pretty much the worse CAD tool ever. I doubt that we'll get an injection-moulded case out of this, but it is fun to imagine that as a possibility.

LOL! I was thinking about searching this topic to check in just this afternoon! I somehow missed your January update. FABULOUS!

I remember seeing info on SCSI converters for non-HDD peripherals that weren't stupidly expensive (+-$70?) a while back. Your new case with opening to support a slotloader laptop CD would kill! A trayloader version as in my pic on the first page would be adapter free/economical by comparison. That pic may be of a caddy loader though, don't recall offhand. My AppleCD SC looks really homely and very dated by comparison to your case. There's no need for the front controls to use it as a CD Player in a Stereo setup as was the case in the day.

Never mind the woodworker comparison, there's no way to do it in less time without setting up and using router jigs or a router table. With the latter you'd still come up short with radiused ends on every groove looking nowhere near Snow White correct. You rock, my man!

This is totally, totally possible. 3D printing gives us a lot of flexibility here - adding a slot and/or flexible push-button to the front would not be difficult. We're talking

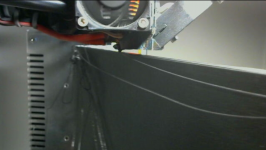

minutes of work. Now adding posts for screws and stuff is more challenging ONLY because of how I'm vertically orienting the prints. If I can print the whole thing flat, that problem basically goes away.

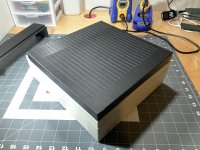

Two Three big challenges: insane amount of print time, difficulty of print, and the $35 worth of material for each time - assuming no failed prints.

That is beyond impressive!

Thank you very much!

-------------

Things to investigate:

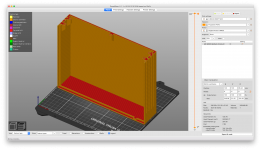

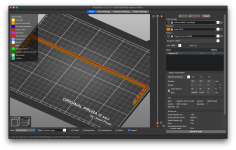

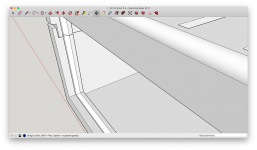

1. Printing in two parts, flat. Will involve generating support material... I'm just not sure how well this will go. Would look something like this. The bed isn't deep enough to print it as one piece so it would need to be two. The green on the left is support material - I'll do a smaller print to test that.

2. Should I make the Apple logo area larger, big enough for an actual Apple badge? Are those obtainable anywhere?

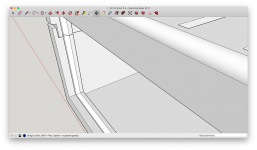

3. Right now, the "back plate" needs to be beveled since we're 3D printing it, so it couldn't accommodate plexiglass.

4. Should I put spots for rubber feet on it? This is easy when printing vertically. The 20SC uses big square feet, I don't know where to get those. The Mac itself uses 1/2" diameter feet which are plentiful. Any thoughts? Anyone care? Here's another one of my designs using rubber feet. SD card indicator for scale.